Industrial construction has long relied on durable roofing materials to protect buildings from weather and wear. With sustainability becoming a major concern for modern industries, questions arise about the environmental impact of Factory Building Roof Tiles . Are they environmentally friendly? Can they be recycled at the end of their lifespan? We are explores these questions, examining the materials, production processes, and potential for recycling of factory roof tiles, as well as their broader impact on sustainable construction practices.

What Materials Are Commonly Used in Factory Roof Tiles?

Factory building roof tiles are made from a variety of materials, each with different environmental implications. Common options include clay, concrete, metal, and polymer-based tiles. These materials differ in durability, energy consumption during production, and recyclability. Understanding the composition of roof tiles is essential to assessing their environmental footprint.

| Material Type | Durability | Recyclability | Environmental Impact |

|---|---|---|---|

| Clay | High | Medium | Moderate |

| Concrete | Very High | Medium | High energy use |

| Metal | High | High | Low to moderate |

| Polymer-based | Moderate | High | Low to moderate |

The environmental friendliness of roof tiles is influenced not only by the material itself but also by the energy and resources used in production. For example, concrete tiles require significant energy to produce, which can increase their carbon footprint, while polymer tiles often have lower energy requirements but may involve synthetic chemicals.

How Does Production Affect Environmental Impact?

Making ASA resin tiles involves several steps in factories. Energy runs the machines that mix and shape the materials. Water cools equipment during the process. Waste appears as scraps or unused bits.

These factors shape the overall effect on the surroundings. Polymer-based tiles like ASA avoid extreme heat needed for some traditional options. This keeps energy use lower in production.

Factories extrude layers to form the tiles. Co-extrusion builds the core and surface together. This method runs efficiently without massive ovens.

Modern setups capture trim edges for reuse. This cuts down on material loss. Some plants recycle water in loops. Emissions get filtered before release.

Compared to firing clay at high temperatures, resin processing demands less fuel. Metal tiles need mining and melting, which adds its own load. ASA tiles start from synthetic bases, shaped mechanically.

At the end of life, these tiles separate easily from other building parts. Grinding turns them into new raw inputs. This closes the cycle somewhat.

Production choices matter. Facilities that prioritize recovery systems leave lighter marks. Energy from cleaner sources helps too.

ASA resin tiles come together balances practical needs with care for resources. Lower heat, reusable scraps, and future recycling all play parts in softening the footprint.Chinese factories often refine these processes. They adapt lines to waste less and run smoother.This keeps the impact in check while meeting demands.Tiles reach sites ready to perform. Their creation story adds to the appeal for mindful projects.

Are Roof Tiles Recyclable?

Recyclability is a key factor in evaluating the environmental friendliness of roofing materials. Most industrial roof tiles can be recycled, though the methods vary depending on material type.

- Clay Tiles: Clay tiles can be crushed and reused in construction aggregates or landscaping. The process is simple but may require energy for transport and processing.

- Concrete Tiles: Concrete tiles are highly durable, and when recycled, they can be repurposed for base layers in roads or new construction materials.

- Metal Tiles: Metal roof tiles are among the most recyclable options. They can be melted down and formed into new sheets or other products.

- Polymer Tiles: Polymer-based tiles can be melted and remolded into new products or construction materials. Recycling rates are higher for polymers that are free from mixed additives.

| Tile Material | Common Recycling Method | Recycling Efficiency |

|---|---|---|

| Clay | Crushing into aggregates | Medium |

| Concrete | Crushing for construction base | Medium |

| Metal | Melting and reforming | High |

| Polymer-based | Remolding or pelletizing | High |

How Do Roof Tiles Contribute to Sustainable Construction?

Roof tiles play a bigger role in green building than just end-of-life recycling. Their real impact shows up over years of use. Tiles that hold strong for decades cut down on repairs or full replacements. This saves raw materials and skips the energy spent on new production.

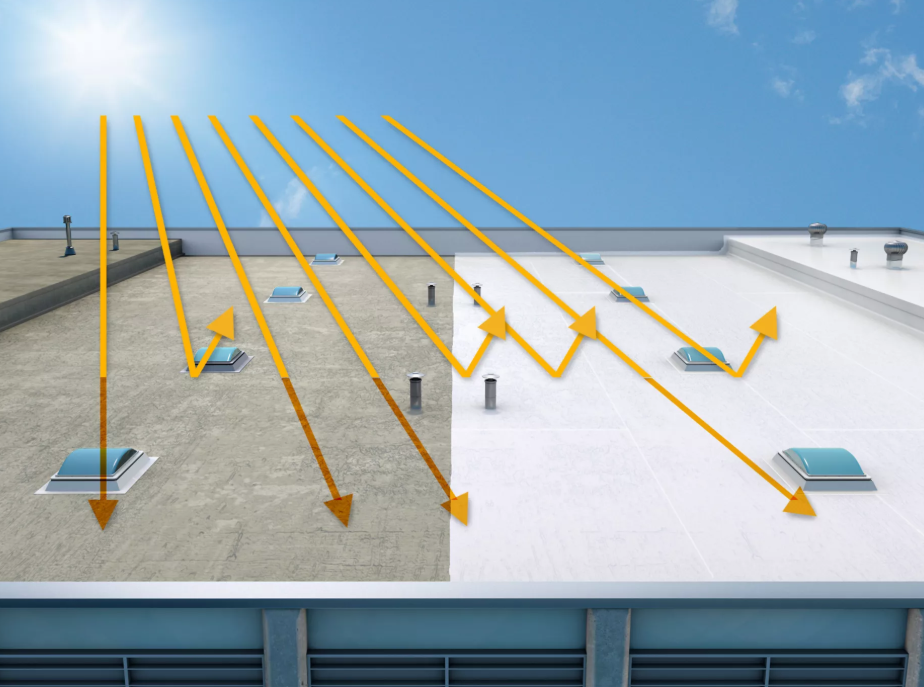

In hot climates, certain tiles bounce back sunlight. Lighter colors or special coatings reflect heat away from the building.

This keeps interiors cooler naturally. Factories or warehouses stay comfortable with less air conditioning. Energy bills drop. Emissions tied to power use fall too.

ASA resin tiles often come in shades that aid this reflection. Large industrial roofs cover wide areas. The cooling effect adds up significantly there.These tiles resist fading from sun exposure. They shrug off heavy rain or wind without cracking. Fewer leaks mean less fixing. Maintenance crews visit rarely.

Homes benefit in similar ways. Roofs on houses handle daily weather.

Long-lasting coverage reduces waste from tear-offs. Energy savings help with heating in cooler seasons too.

Overall building life improves. Structures stand longer with reliable tops. This aligns with wider sustainability goals.

Chinese ASA resin tiles fit into eco-focused projects smoothly. They combine strength with practical features like heat reflection.Builders choose them for roofs that support lower resource use day after day. The benefits build quietly over the years.

Can Roof Tiles Be Part of Circular Construction Practices?

Circular construction emphasizes reducing waste and maximizing resource reuse. Factory roof tiles fit into this model through recyclability and long-term durability. Recycled tiles or crushed aggregates can replace raw materials in new projects, reducing the need for virgin resources. Metal tiles, in particular, can be repeatedly recycled without losing material quality, aligning well with circular economy principles.

| Material | Suitability for Circular Practices |

|---|---|

| Clay | Medium – can be crushed and reused |

| Concrete | Medium – suitable for aggregates |

| Metal | High – can be recycled indefinitely |

| Polymer | High – can be remolded if uncontaminated |

Incorporating recycled tiles into new construction reduces waste sent to landfills and decreases the extraction of raw materials. Factories adopting this approach can demonstrate environmental responsibility while potentially lowering costs associated with material procurement.

Are There Innovations in Eco-Friendly Roof Tiles?

New ideas keep emerging in roofing materials. Builders and makers look for ways to lighten loads and cut resource use.

Lighter tiles make a difference. They weigh less than older styles. Trucks carry more at once. Fuel for shipping drops.

Composite blends mix strengths. Some combine plastics with other elements. These hold up against weather while allowing reuse at end of life.

Surface treatments boost reflection. Special layers send sunlight back. Buildings stay cooler inside. This trims energy for fans or units in warm areas.

Some explore polymers that break down easier. Others focus on full loops for recycling. Factories test ways to reclaim old tiles fully.

Designs stretch service years. Tougher builds mean fewer swaps. Maintenance stays low. This saves effort and parts over time.

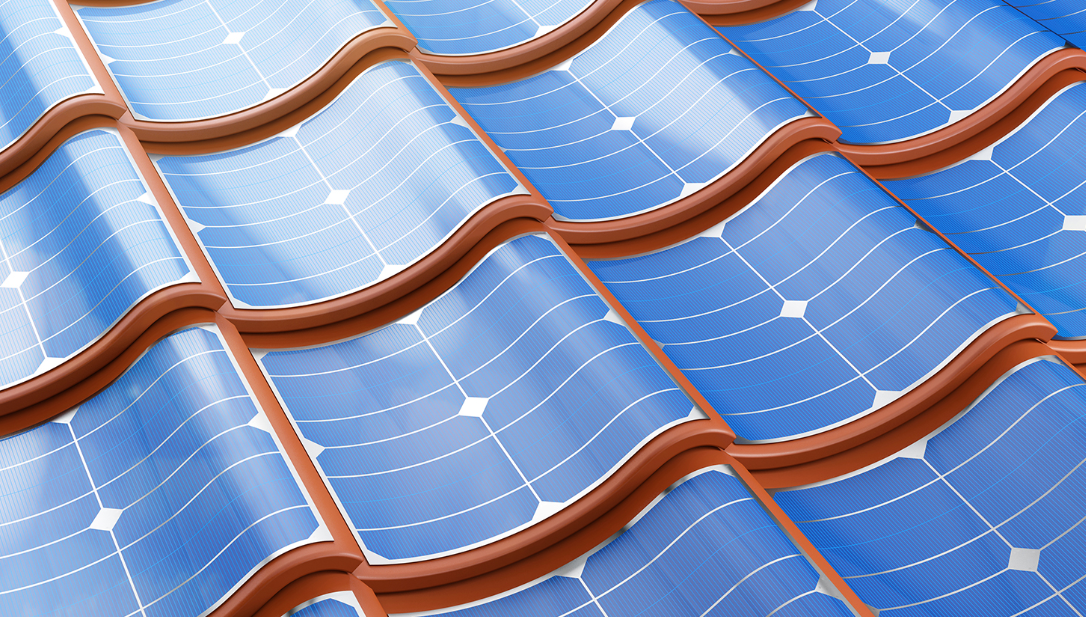

Integrated options appear too. Tiles embed solar capture. They generate power while covering roofs.

- Natural sources inspire alternatives. Bamboo forms flatten into covers. They renew quickly.

- Synthetic slates mimic looks with recycled content.

- Chinese ASA resin tiles join this wave. Makers refine layers for better reflection and strength.

These steps soften marks on resources. Long use, smart shipping, and recovery paths all add up.Fresh approaches keep coming. They blend daily needs with care for the bigger picture. Buildings gain from these shifts in quiet ways.

What Factors Should Be Considered When Selecting Eco-Friendly Roof Tiles?

Selecting environmentally friendly roof tiles involves multiple considerations:

- Material Composition: Evaluate the environmental impact of raw materials and whether the tile contains recycled content.

- Production Process: Assess energy use, emissions, and waste generated during manufacturing.

- Durability: Longer-lasting tiles reduce replacement frequency and resource use.

- Recyclability: Consider whether the tile can be recycled at the end of its life and how easily it can enter recycling streams.

- Energy Efficiency: Tiles that improve insulation or reflectivity can reduce operational energy use.

- Compatibility with Circular Practices: Tiles should integrate with recycling and reuse strategies.

| Selection Factor | Impact on Sustainability |

|---|---|

| Material Composition | Determines overall environmental footprint |

| Production Process | Influences energy and emissions |

| Durability | Reduces replacement and resource consumption |

| Recyclability | Supports circular construction practices |

| Energy Efficiency | Lowers operational energy use |

| Circular Practice Compatibility | Enhances long-term sustainability |

English

English Español

Español عربى

عربى

Email:

Email: Phone:

Phone: Adress:

Adress: