Square Meter Calculation

Shippment Reference,

20’ container

Total ** G, ** M, packed as two piles in one container, for reference only

40’ container,

Total ** G, ** M, packed as two piles in one container, for reference only

from NINGBO to DUBAI, UPDATE WEEKLY BY NINGBO *** SHIPPING LLC

For more port freight rates, please get in touch with us + Container and product deconstruction diagrams, rulers, port-to-port maps

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

View Item Data

|

Material

|

Polycarbonate

|

|

Weight

|

1.2kg/MM/M² (per thickness)

|

|

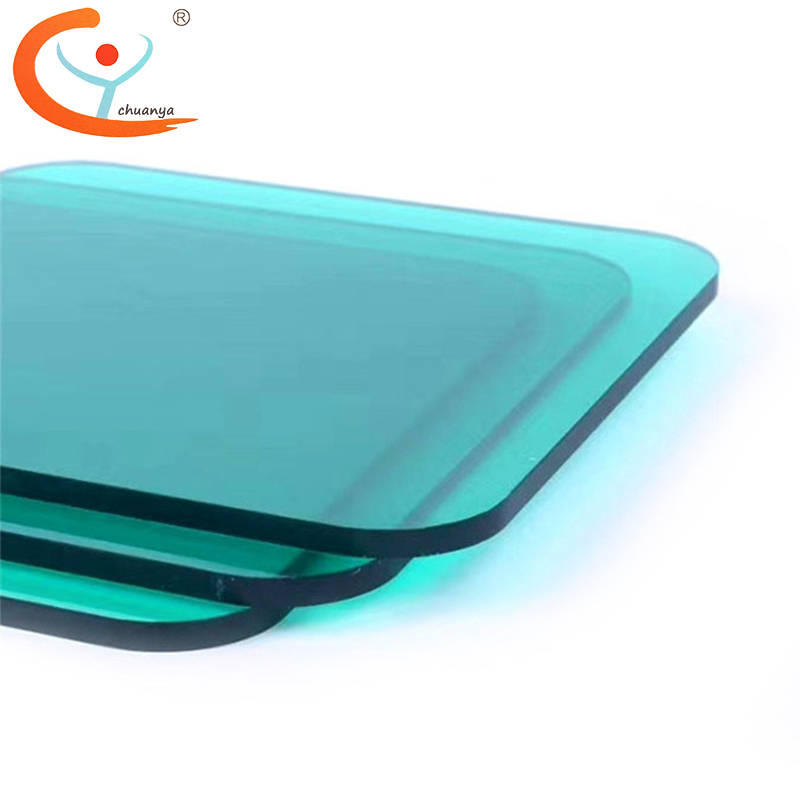

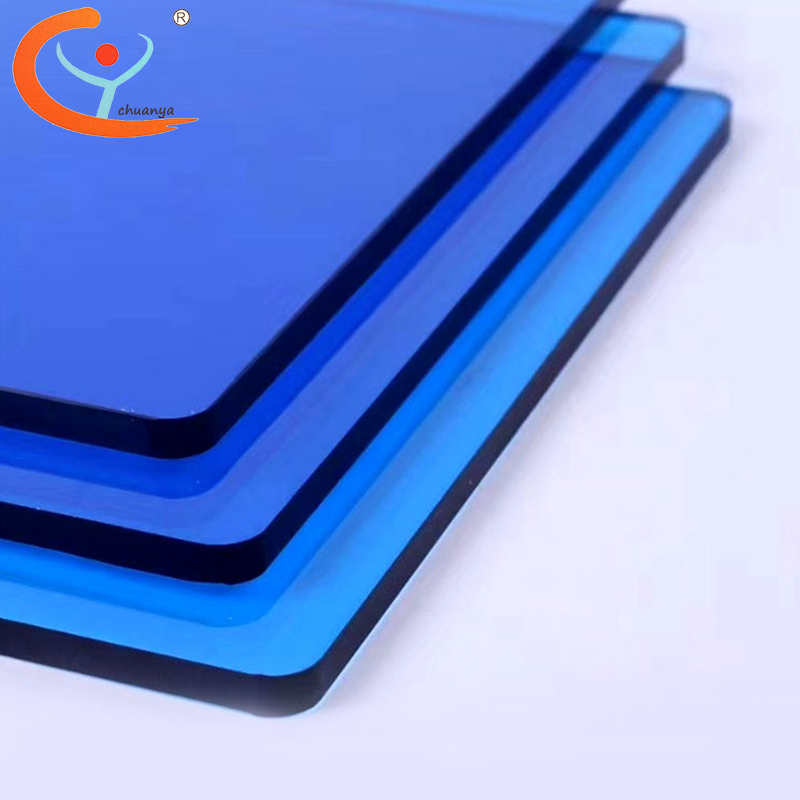

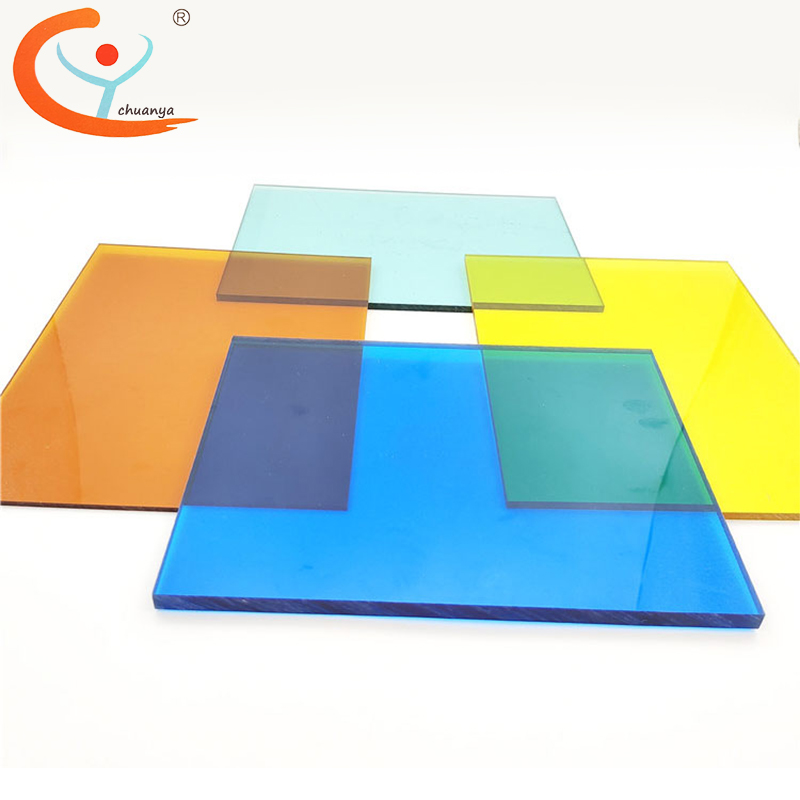

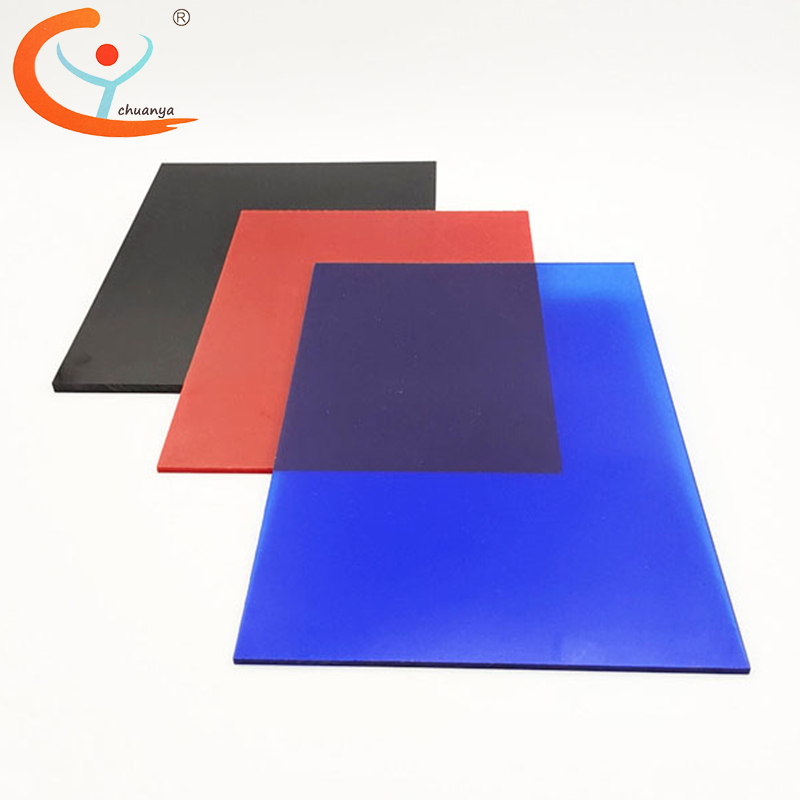

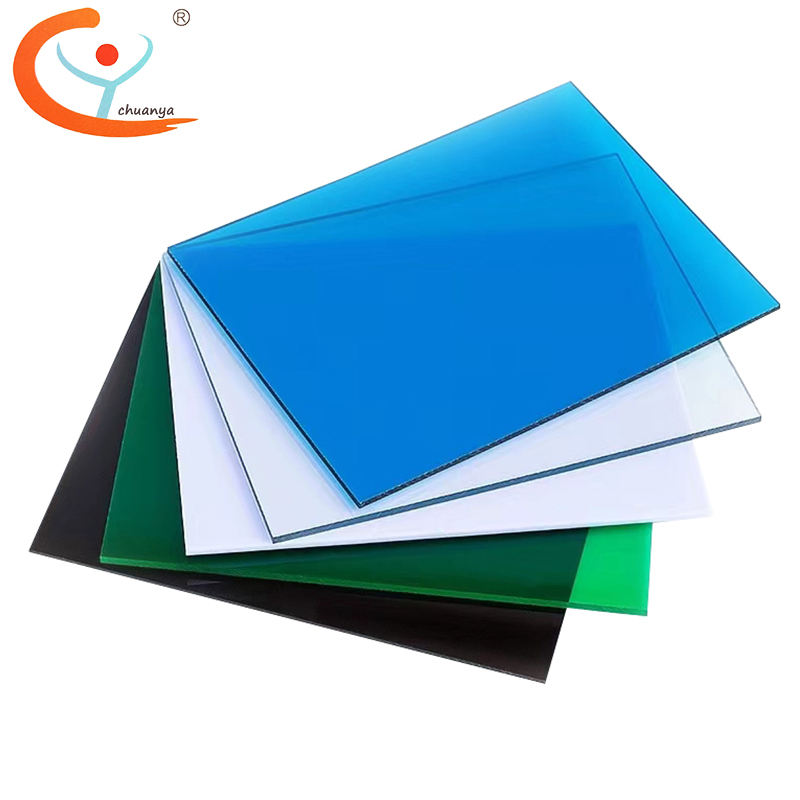

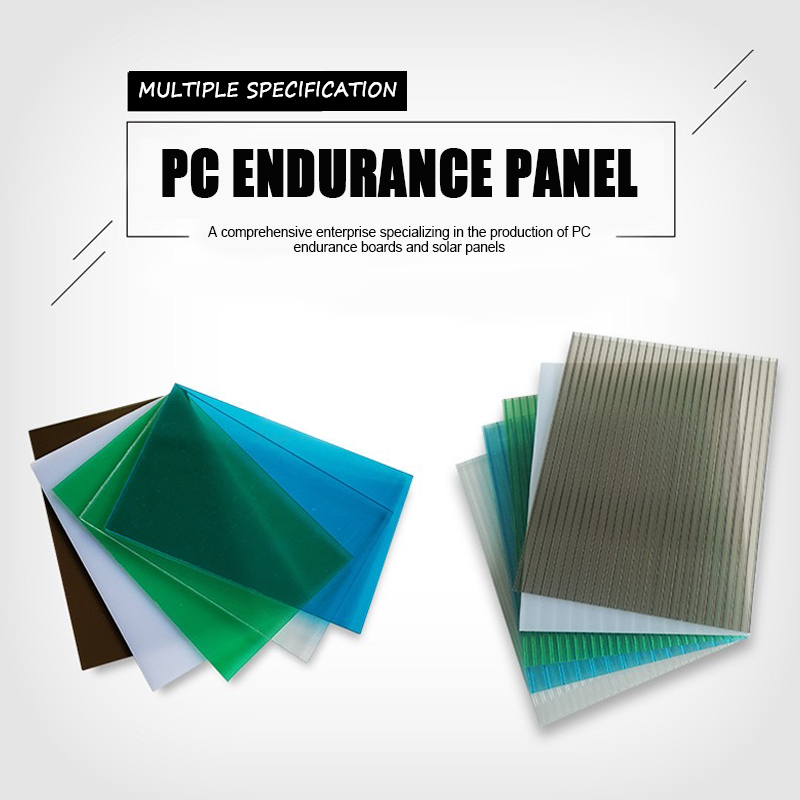

Color

|

Transparent/ Grey/ White/ Blue/ Green/ Brown

|

|

Thickness

|

1.2MM/ 1.5MM/ 2.0MM/ 2.5MM/ 3.0MM/ 3.5MM/ 4.0MM/ 4.5MM/ 5MM

|

|

Usage

|

Rooftop lighting and insulation/ External Wall/ Fence/ Telephone booths/ advertising billboards/ light box advertising/ exhibition layout/ Applicable to instruments/ meters/ high and low voltage switch cabinet panels/ LED screens and military industry & etc.

Suitable for deep processing such as thermoforming and blister forming;

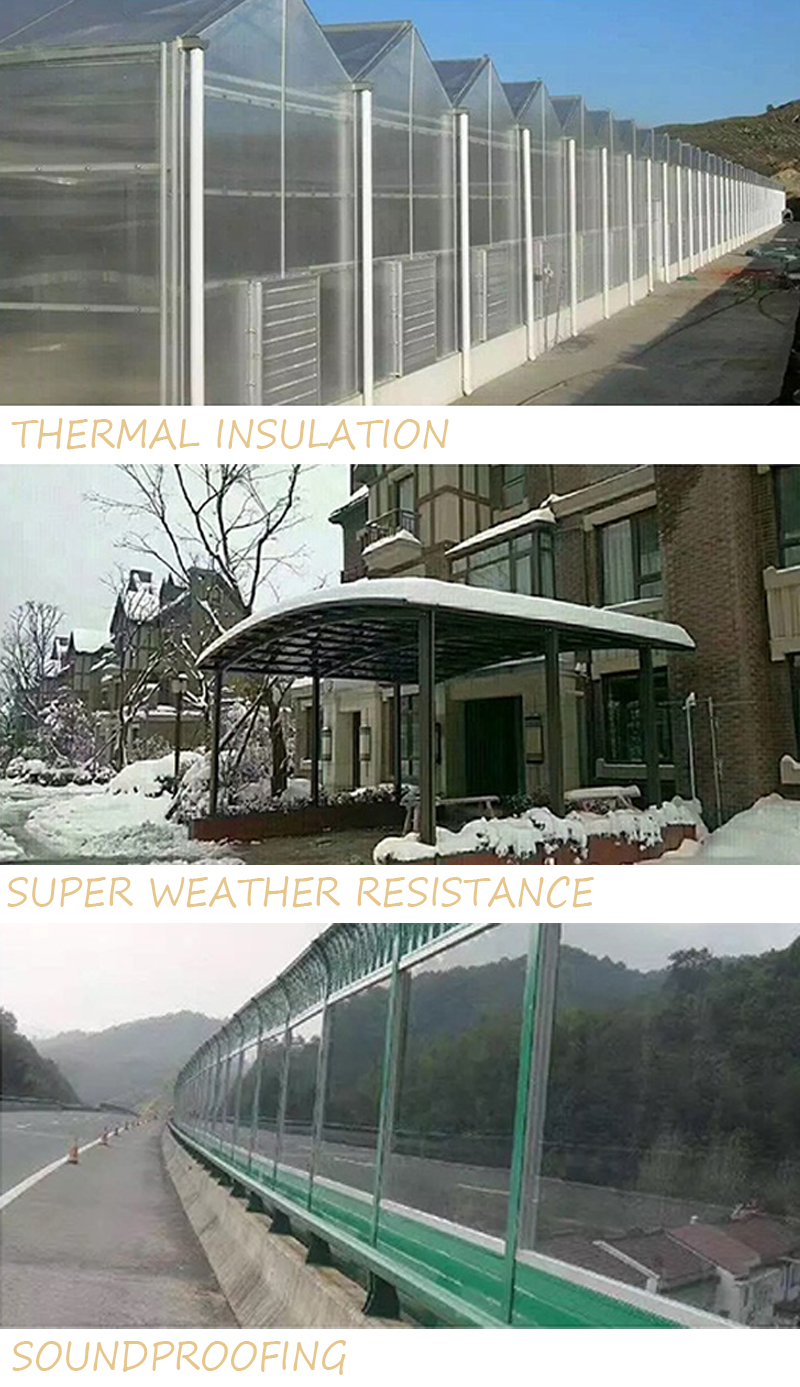

Suitable for lighting and rainproof ceilings such as awnings, carports, and waiting sheds;

Suitable for noise barriers on highways and urban elevated roads;

Suitable for agricultural greenhouses and breeding greenhouses;

Suitable for modern ecological restaurant ceilings;

Widely used for curtains.

|

|

Width

|

0.84 - 0.98 M

|

|

Length

|

6M, Customized Available

|

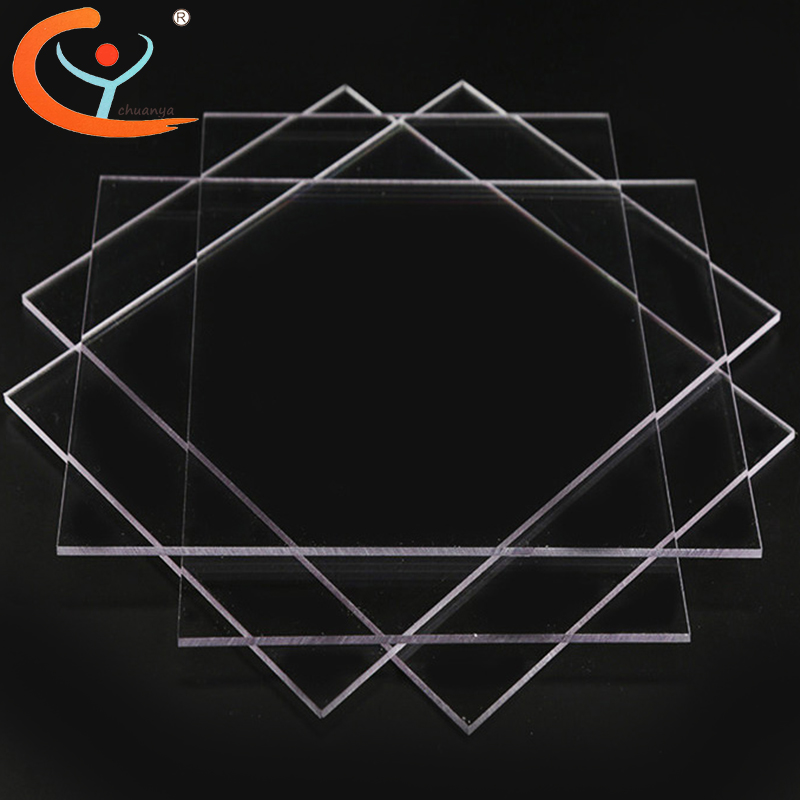

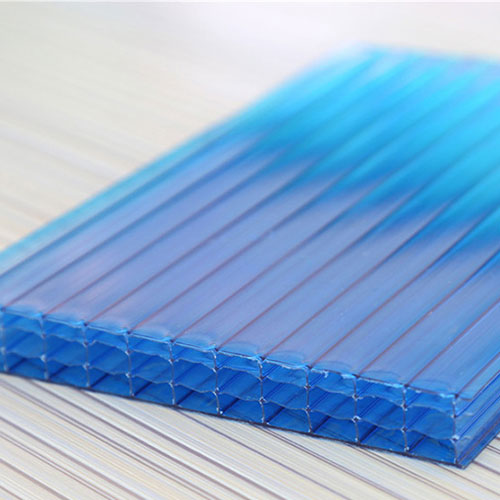

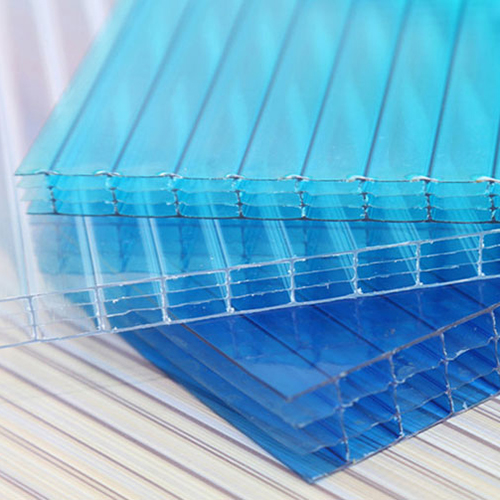

PC Endurance Panels are a type of skylight material made of Polycarbonate.

PC Endurance Panel (also known as polyester fiber endurance board, PC board, polycarbonate, solid board, bulletproof glass, cabron board, plastic solid board, polycarbonate board, aviation perspective board, endurance hollow board) is made of high-performance engineering plastic polycarbonate or polycarbonate-----acid.

Features:

Impact resistance, unbreakable strength exceeds hundreds of times of tempered glass and acrylic board, tough and safe, anti-theft, and bulletproof effect is the best.

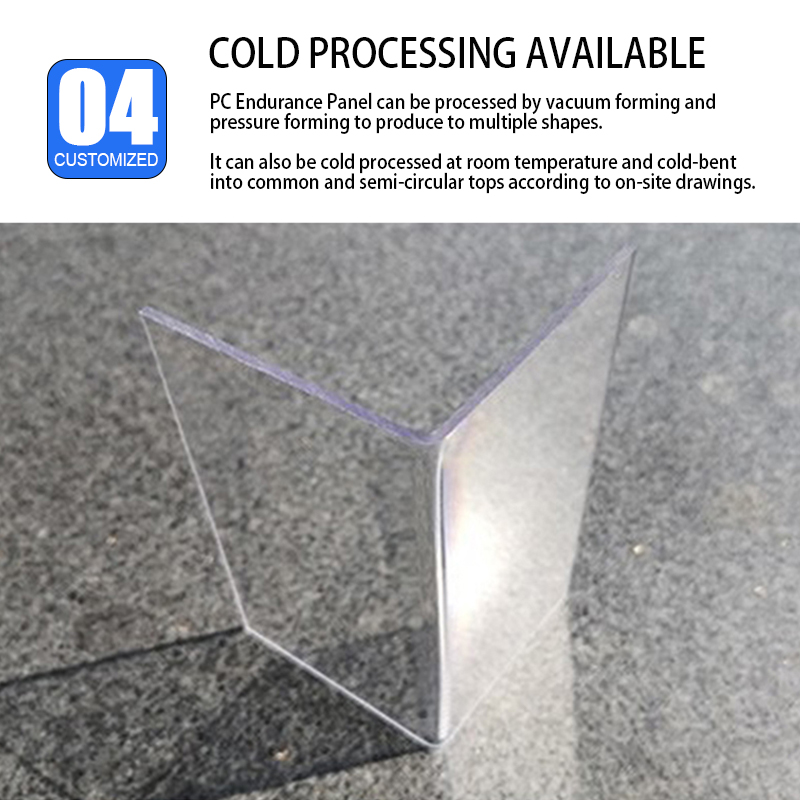

Arched and bendable: good processability, strong plasticity, can be bent into arches, semicircles and other styles according to the actual needs of the construction site.

Endurance board can be made up to 3 meters wide and any length, and can also be made into U-shaped endurance board to effectively improve the problem of thermal expansion and contraction

Product Features

1. Good light transmittance. Polycarbonate is the main raw material and has high lighttransmittance.

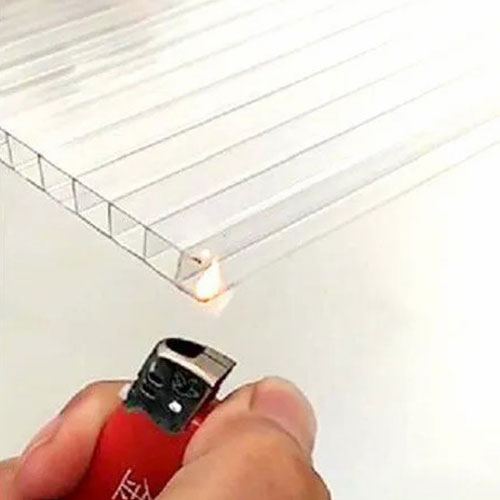

2. Good flame retardant performance, B1 level, difficult to burn materials, fire suffocationlevel, will automatically extinguish after leaving the fire source, or extinguish within 10seconds, not easy to burn

3. Strong impact resistance, not easy to break under the impact of gravel and hail.

4. The processable PC board can be processed by vacuum forming method and pressureforming method. Parts of various shapes can also be cold-bent at normal temperature. Thecold-bending method can be used at the construction site according to the design drawingto install arch and plate circles. Shaped roof and windows.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

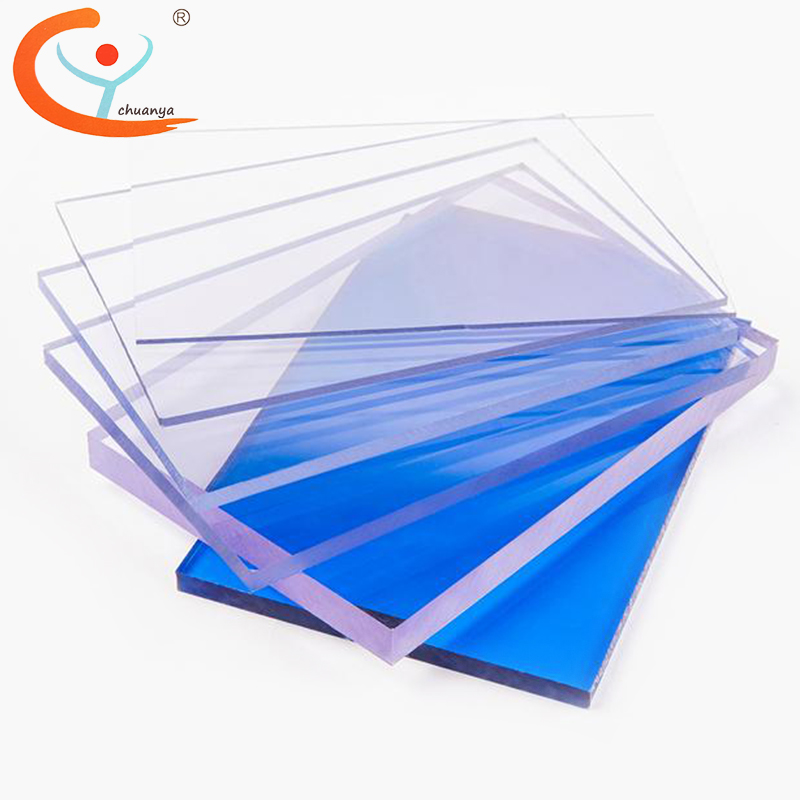

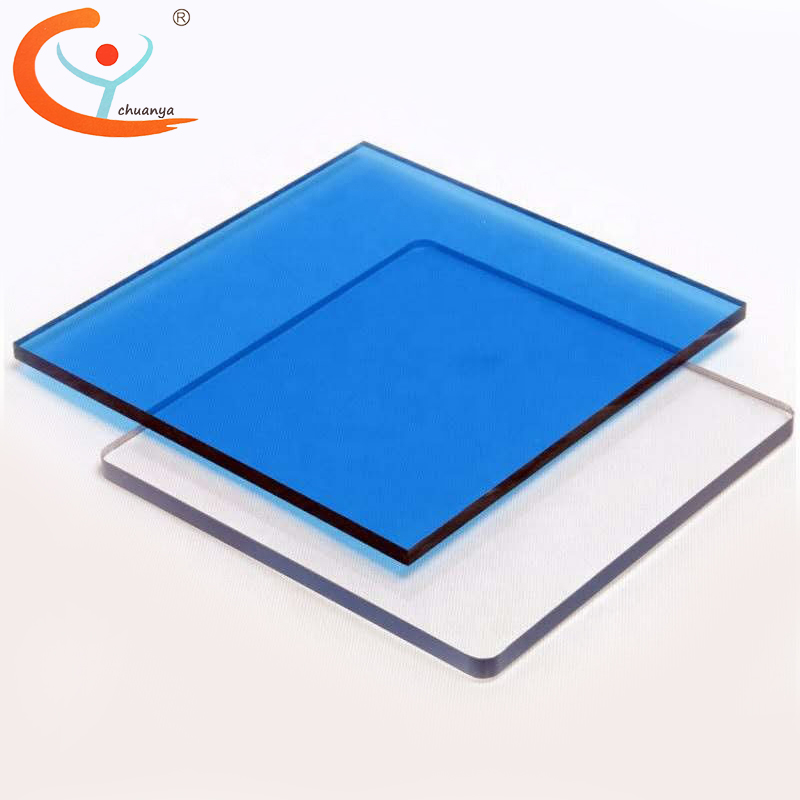

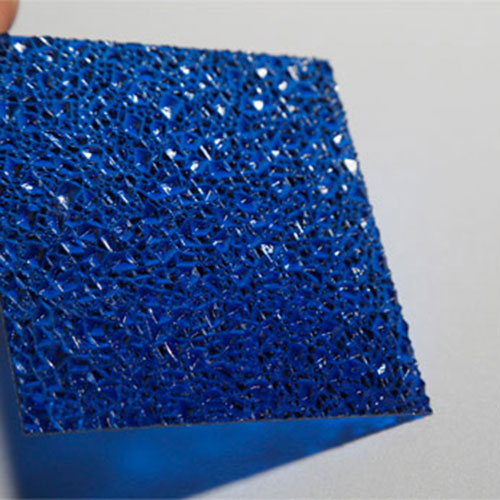

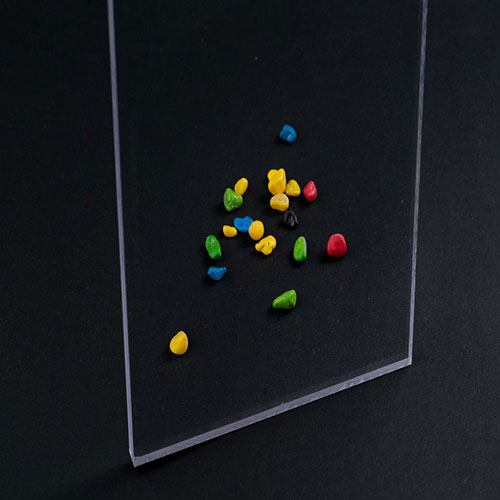

Color Reference

PC Endurance Panel, Chuanya Roof Tile

|

| PC Endurance Panel with multiple color for reference, Chuanya Roof Tiles |

PC Endurance Panel, Roof Tile with leading productiontechnology and equip.ment, set research anddevelopment, produc-tionand sales of modernenterprises

(1) Light transmittance: The light transmittance of polycarbonate sheets can reach up to 89%, which is comparable to glass. UV coated sheets will not turn yellow, fog, or have poor light transmittance when exposed to sunlight.

After ten years, the light transmittance loss is only 10%, while the loss rate of PVC is as high as 15%-20%, and that of glass fiber is 12%-20%.

(2) Impact resistance: The impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic sheets of the same thickness, and 2-20 times that of tempered glass.

It will not crack even if it is dropped from two meters below with a 3kg hammer. It is known as "unbreakable glass" and "ringing steel".

(3) Anti-ultraviolet: One side of the PC sheet is co-extruded with an anti-ultraviolet (UV) coating, and the other side has an anti-condensation treatment, which combines anti-ultraviolet, heat insulation and anti-fog functions.

It can block ultraviolet rays from passing through and is suitable for protecting valuable artworks and exhibits from damage by ultraviolet rays.

(4) Light weight: The specific gravity is only half of that of glass, saving the cost of transportation, handling, installation and supporting frame.

(5) Flame retardant: The national standard GB50222-95 confirms that the endurance board is a flame retardant level 1, that is, B1 level.

The ignition point of the PC board itself is 580℃, and it will extinguish itself after leaving the fire. It will not produce toxic gases when burning and will not help the spread of the fire.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

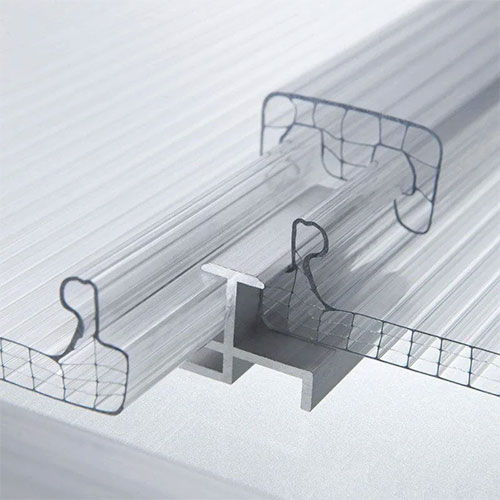

Installation

|

|

|

|

|

| Installation for PC Endurance Panel used for daylighting, Chuanya Roof Tiles |

|

|

|

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

Applications of PC Endurance Panel:

1. Generally used in machine protection, windows, windshields, lighting fixtures, signs, and partitions for walls and doors

2. Substrates for hardening, antistatic, and atomized surface treatment

3. As a protective layer to prevent accidental damage to the protected product

4. Easy to heat, cold bend, and machine

Available sizes, colors, and UV:

1. The sheet can be provided with a thickness of 1.5~16.0mm and a size of 1220*2440mm. Other sizes and colors are available upon request.

2. The sheet can be provided with double-sided UV, single-sided UV, and UV-free products

Hangzhou Chuanya Building Materials Co., Ltd, professionally produced PC Endurance.

The universal endurance panel is made of 100% new imported high-grade raw materials, with a 10-year warranty at least.

It has the characteristics of high transparency, light weight, impact resistance, sound insulation, heat insulation, flame retardancy, and anti-aging.

It is a new type of material with extremely excellent comprehensive performance, energy saving and environmental protection, and has advantages that other building decoration materials (such as glass, organic glass, etc.) cannot match.

It is widely used in greenhouses/industrial plants, decoration, advertising, signs, parking sheds, channel lighting ponchos, residential buildings, commercial building lighting canopies, exhibition lighting, stadiums, swimming pools, warehouse lighting roofs, factories, stadiums, lighting ceilings and sunshades, agricultural greenhouses, breeding and flower sheds, as well as public facilities such as telephone booths, bookshelves, newsstands, stations, highway sound insulation screens, and advertising decoration fields.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

|

| Production for PC Endurance Panel After mold shaping, Chuanya Roof Tiles |

|

|

|

|

|

| Transparent PC Endurance Panel in Production, Chuanya Roof Tile |

Production of Surface Frosting for PC Endurance Panel, Chuanya Roof Tile |

Production Process Forming through a sheet mold, Chuanya Roof Tile |

The Production Process Forming through a sheet mold, Chuanya Roof Tile |

How does PC Endurance Panel produce?

First of all, the main raw material for the production of PC endurance panel should be polycarbonate, and other additives may need to be added to improve performance, such as UV inhibitors, flame retardants, etc.

Then, the production process usually includes several steps: raw material pretreatment, melt extrusion, molding, post-processing, etc.

However, the specific steps may need to be divided in more detail. For example, the production of polycarbonate itself is obtained through polymerization, but here the user is asking about the manufacture of endurance sheet, that is, the process of processing polycarbonate into sheet.

So it may be necessary to start with the preparation of raw materials, such as drying and mixing, and then make sheets through extrusion molding or compression molding, and then carry out subsequent processing such as cooling, cutting, surface treatment, etc.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

Importance in Production Profress

Raw material preparation,

Base resin selection,

Mainly use bisphenol A polycarbonate (BPFC) or halogen-free environmentally friendly PC resin, and select different grades according to application requirements (such as light transmittance, flame retardancy).

Additive preparation,

UV-resistant agent (such as benzotriazole): absorbs UV light, prevents yellowing and embrittlement, and is essential for outdoor panels.

1) Flame retardant (such as phosphate or magnesium hydroxide): improves fire rating (such as UL94 V-2 grade).

2) Toughening agent (such as ASA or MBS): improves low-temperature impact resistance.

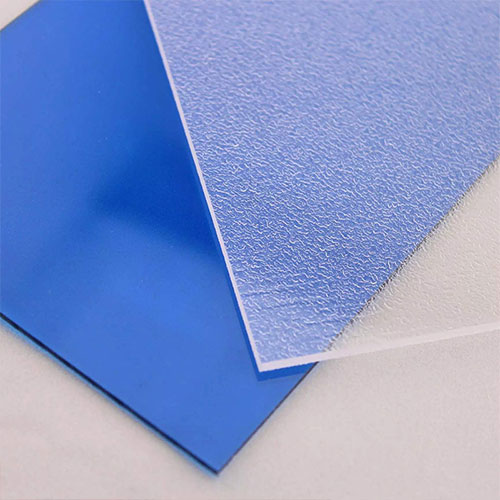

3) Color/shading agent: used for colored or frosted effect panels, achieved through pigments or pearlescent powder.

4) Antistatic agent: reduces surface charge accumulation, suitable for electronic equipment housing. Pretreatment

After the resin and additives are mixed in proportion, dry at 120°C for 4-6 hours to remove moisture (PC moisture absorption rate is about 0.1-0.2%) and prevent bubbles from forming during melting.

2. Melt extrusion molding

Twin screw extrusion system,

1) Temperature control: barrel segment heating (feeding zone 160℃, compression zone 180℃, discharge zone 200℃) to ensure complete melting of resin (glass transition temperature Tg≈147℃).

2) Screw design: exhaust screw is used to discharge volatile gases; multi-stage temperature gradient controls melt fluidity.

3) Multi-layer co-extrusion technology (optional)

Combined with different functional layers (such as transparent PC substrate + anti-UV coating + heat insulation EVA layer), multi-cavity mold is extruded synchronously to achieve composite structure.

Adhesive (such as polyurethane glue) or hot pressing process is used between layers to enhance bonding strength.

3. Molding and shaping

Mold molding,

1) The plate mold is designed with an open cross-section, and the cooling water channels are evenly distributed to ensure rapid cooling (rate of about 5-15℃/min).

2) Thickness control: The screw speed (40-200 rpm) and the traction speed (1-5 m/min) are linked and adjusted, with an accuracy of ±0.1mm.

Quenching process

3) The molten PC is rapidly cooled to below room temperature in the mold, and quickly crystallizes and shapes to avoid warping caused by chain segment relaxation.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

|

|

|

|

| PC Endurance Panel Used Balcony Awning, Chuanya Roof Tile |

PC Endurance Panel Used Eaves Ridge with Rain protection, Chuanya Roof Tile |

PC Endurance Panel Used on Window Rain Protection, Chuanya Roof Tile |

PC Endurance Panel Used for Daylighting, Chuanya Roof Tile |

V. Quality Inspection

1. Physical Performance Test,

1) Light transmittance: ASTM D1003 standard, high-quality sheet ≥89%.

2) Bending strength: ISO 527 test, ≥120 MPa (2.8mm thickness).

-Heat deformation temperature: GB/T 1670, ≥135℃ (1.82MPa load).

2. Environmental tolerance verification,

1) QUV aging test: After 2000 hours of ultraviolet + condensation water exposure, the yellowing index ΔYI≤2.

2) Salt spray test: 5% NaCl solution sprayed for 96 hours, no corrosion marks on the surface.

VI. Environmental protection and recycling

Sustainable development measures,

3) Use bio-based polycarbonate (such as carbonate monomers from castor oil) to reduce oil dependence.

4) Production waste is re-granulated after crushing, and the recycling rate can reach more than 30%.

Application examples,

5) Architecture: lighting ceiling, sound insulation barrier (multi-layer co-extrusion structure, sound insulation of 40dB).

6) Transportation: car windshield (laminated PC/glass composite material, impact resistance is 10 times higher than glass).

7) Electronics: mobile phone screen protector (anti-scratch coefficient>9H, light transmittance>92%).

Through the above process, PC endurance board can achieve the characteristics of high strength, high toughness and long life, becoming an irreplaceable composite material in modern industry. Technological innovation continues to promote its application expansion in the fields of lightweight and intelligent.

Daylighting Roof Tile -- > PC Endurance Panel made by Hangzhou Chuanya Building Material Co., Ltd

Email:

Email: Phone:

Phone: Adress:

Adress: