Square Meter Calculation

Shippment Reference,

20’ container

Total ** G, ** M, packed as two piles in one container, for reference only

40’ container,

Total ** G, ** M, packed as two piles in one container, for reference only

from NINGBO to DUBAI, UPDATE WEEKLY BY NINGBO *** SHIPPING LLC

For more port freight rates, please get in touch with us + Container and product deconstruction diagrams, rulers, port-to-port maps

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

View Item Data

|

Model

|

MY820/ MY840/ MY-760Fold Corner/ MY-820Fold Corner/ MY-470/ MY-750/ MY-820Corrugated/ MY-950/ MY-980/ MY-1025/

MY-980High Wave/ MY-820Cover/ MY-900/ MY-840Fold Corner/ MY-970/ MY-860/ MY-1050/ MY-750

|

|

Material

|

Unsaturated Polyester Resin/ UV resistant film/ Fiberglass Roving

|

|

Weight

|

1.5KG/MM Standard, 1.1KG/MM Non-standard

|

|

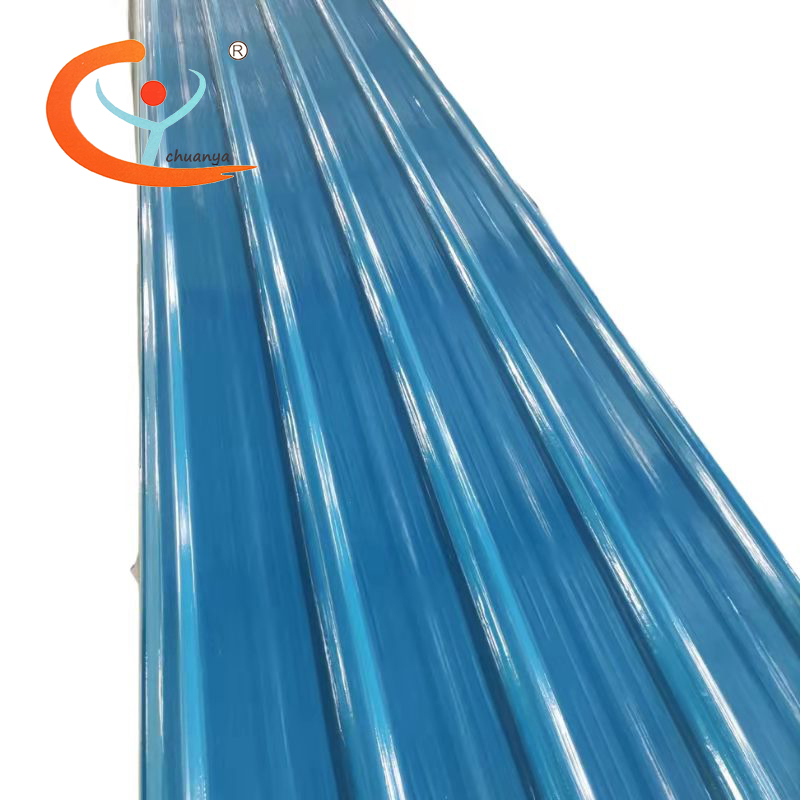

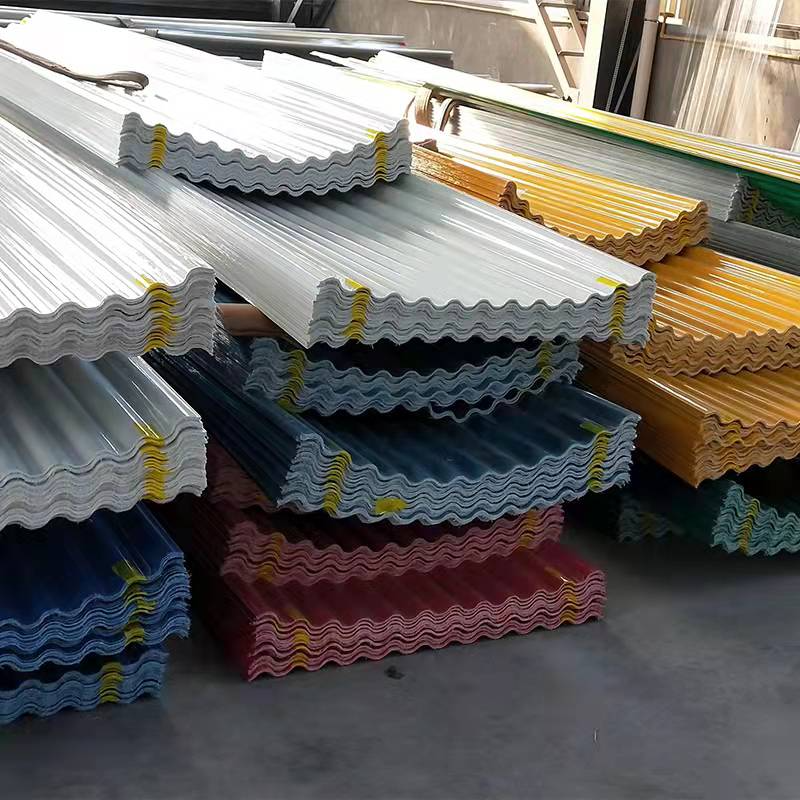

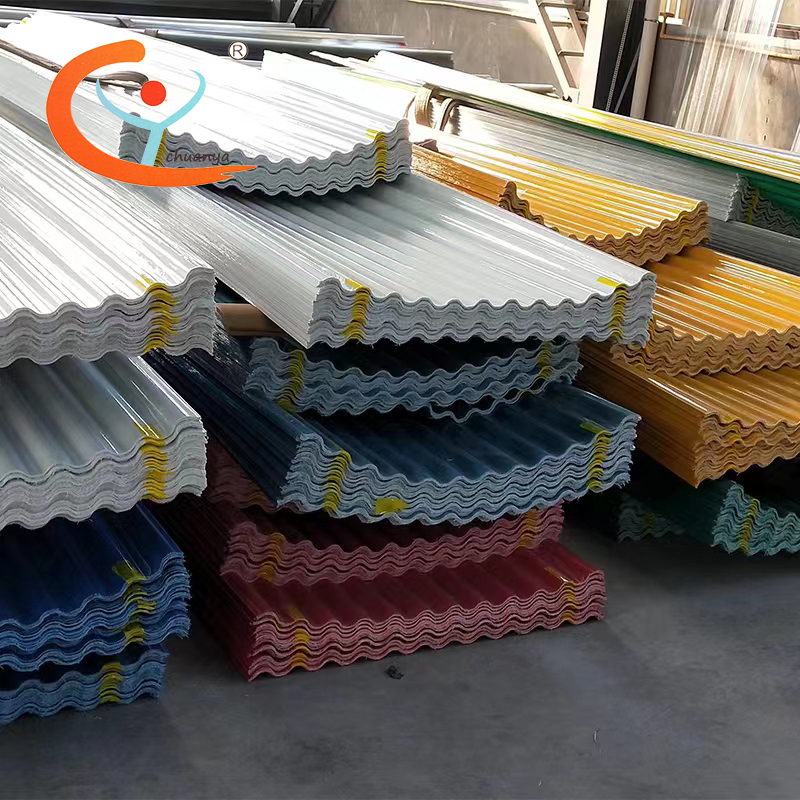

Color

|

Transparent/ Grey/ White/ Blue/ Yellow

|

|

Thickness

|

0.8 - 3.0MM

|

|

Usage

|

Rooftop lighting and insulation/ External Wall/ Fence & etc.

|

|

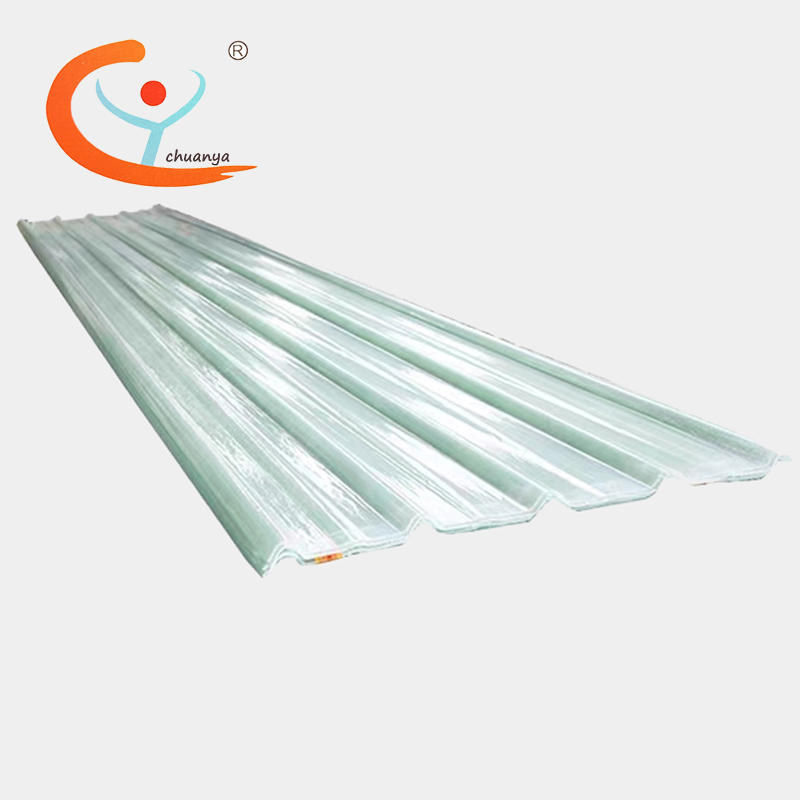

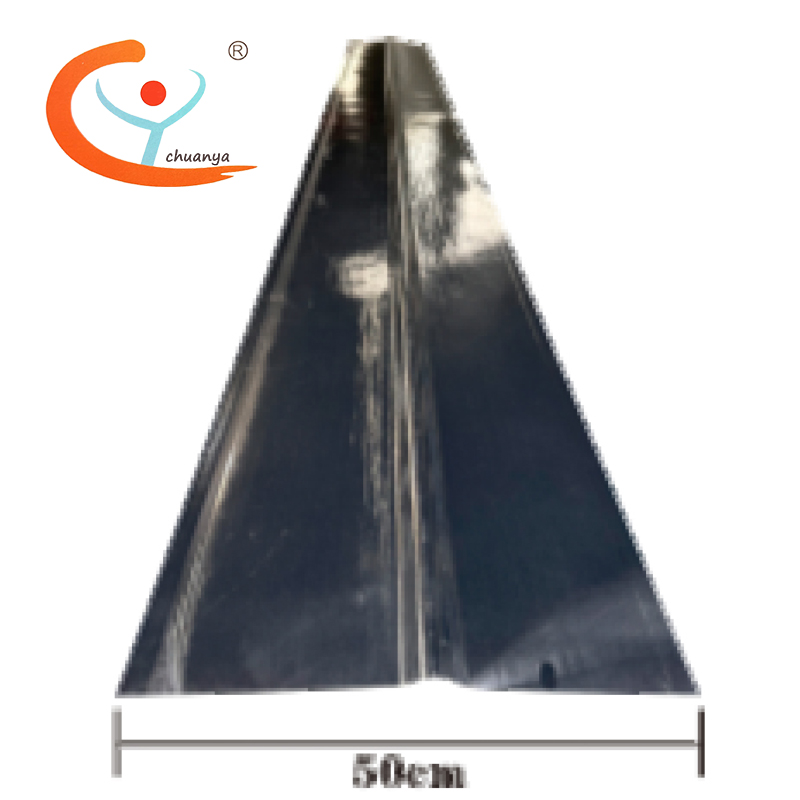

Width

|

0.84 - 0.98 M

|

|

Length

|

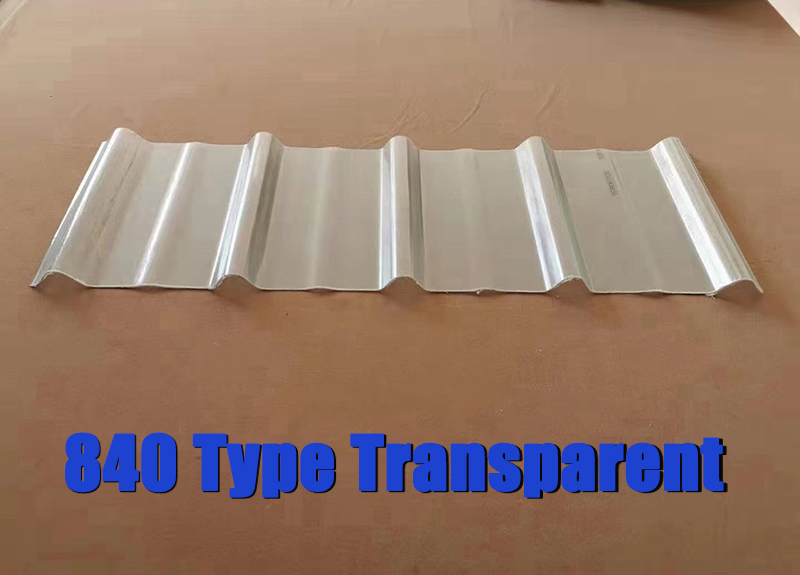

840 type Corrugated Distance 210MM, height 25MM

980 type Corrugated Distance 245MM, height 35MM

Customized Available, stock 6M

|

FRP Lighting Tiles are a type of skylight material made of fiberglass reinforced plastic (FRP).

It is also known as fiberglass or transparent tiles, anti-corrosion tiles, and sunshine tiles.

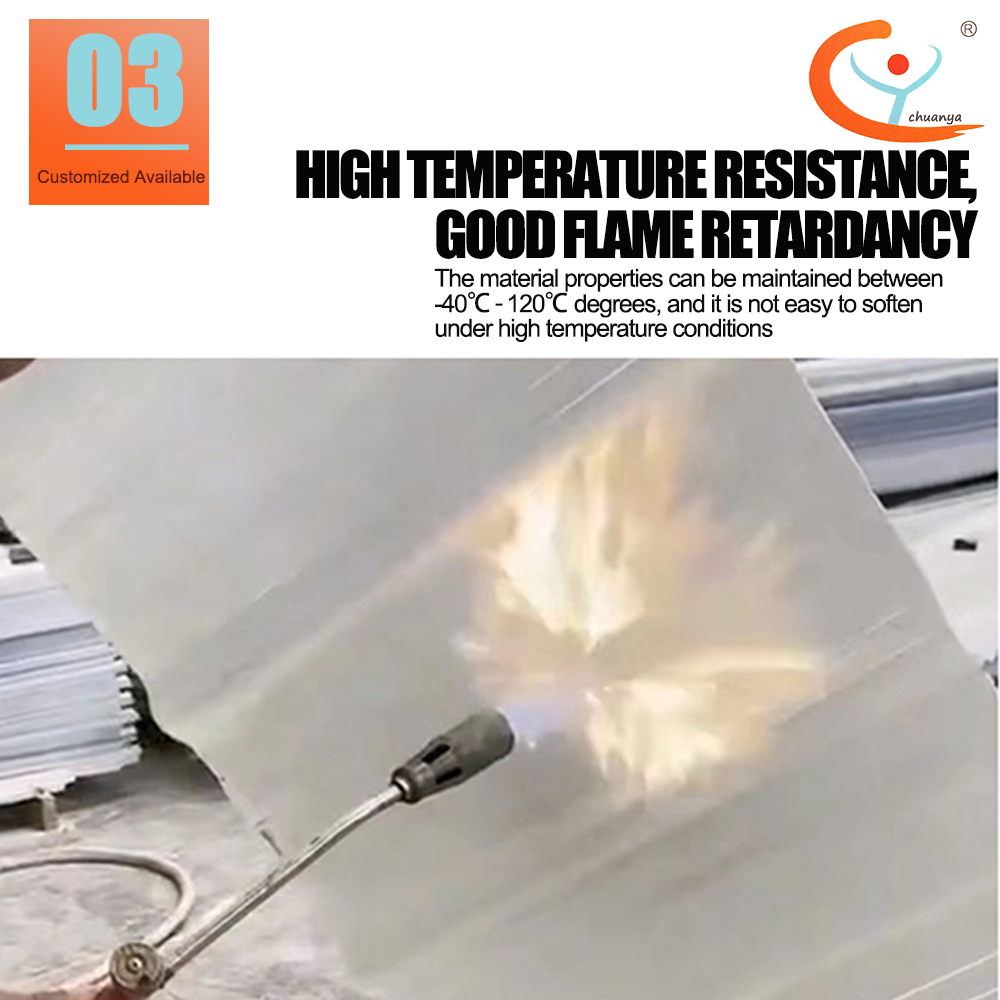

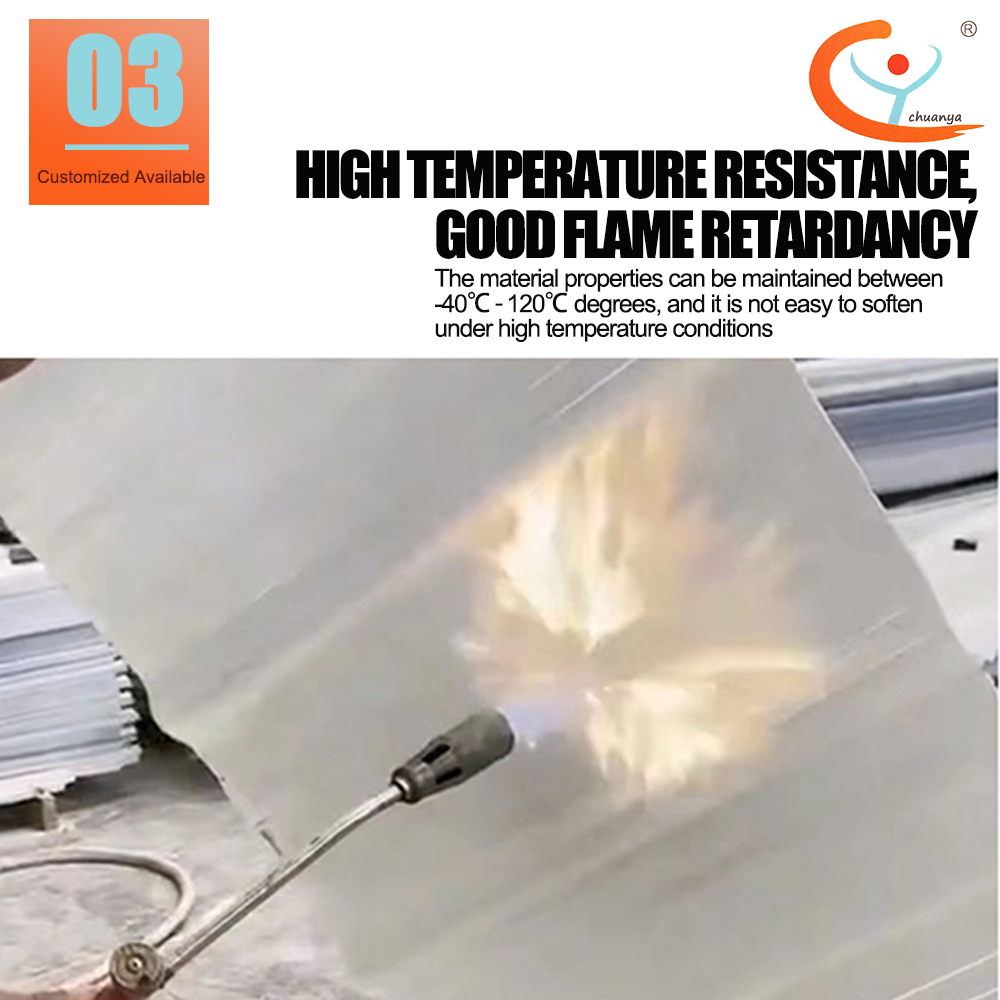

This material has excellent temperature resistance and can work stably in a temperature range of -40℃ - 120℃.

Due to its unique properties, FRP Lighting Tiles have been widely used in many fields such as industrial plants, large markets, municipal projects, commercial facilities, and greenhouses for flowers and vegetables, providing a variety of bright lighting options for buildings.

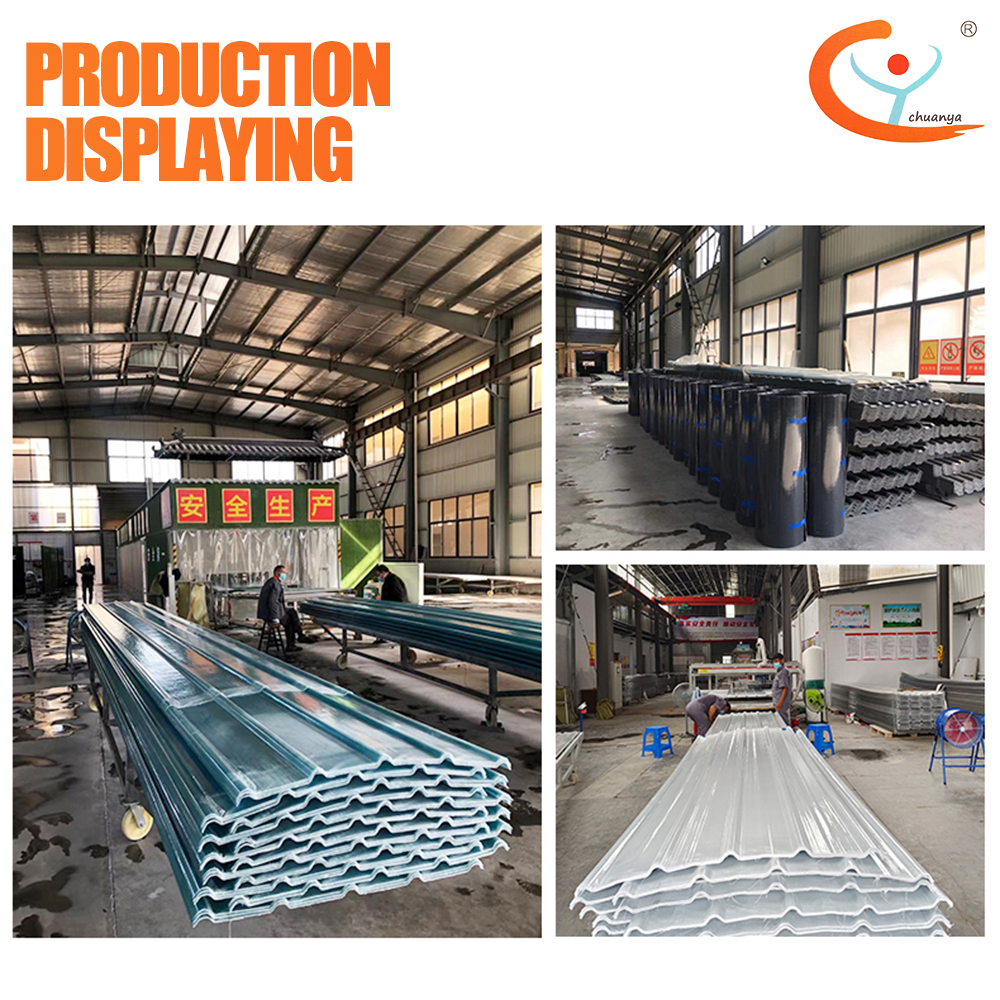

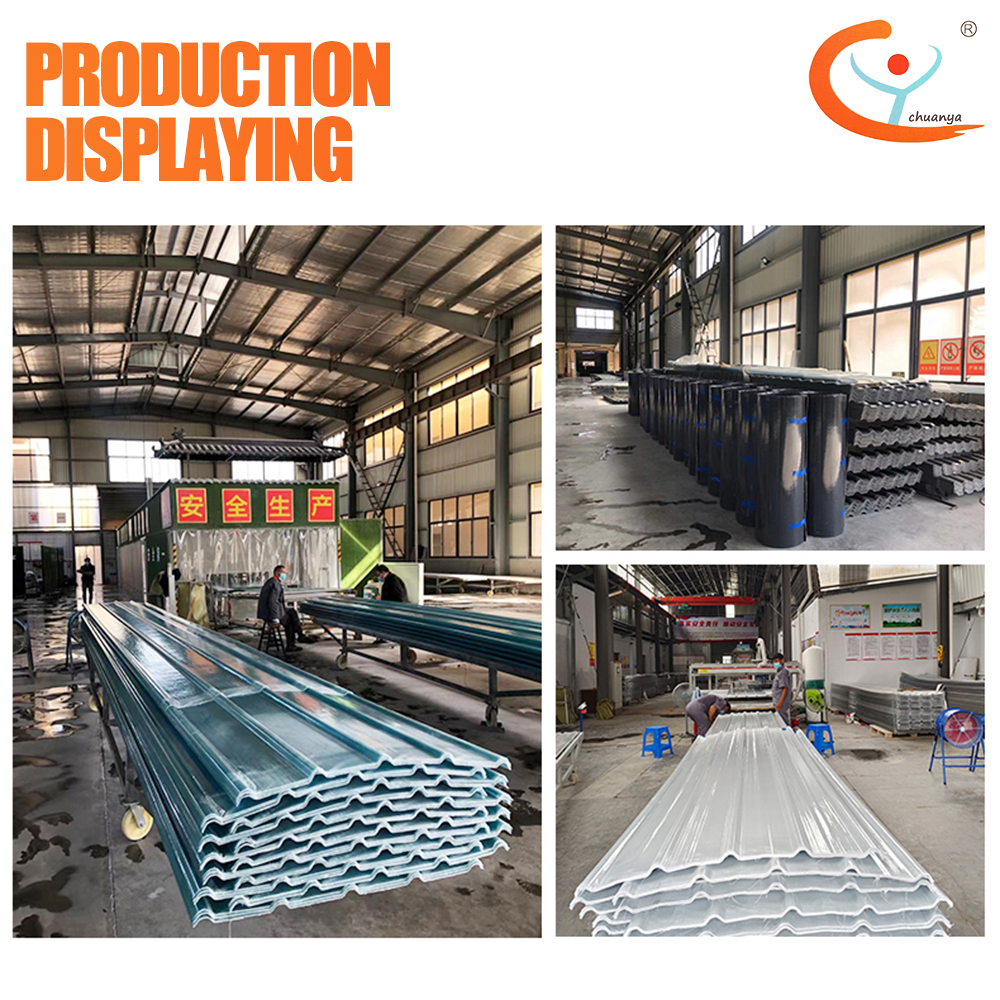

Exquisite production technology of FRP Lighting Tiles, In the production process of FRP FRP Lighting Tiles, we selected the most advanced full set of production equipment in the industry provided by Boao Group,

with a total length of up to 65 meters,

far exceeding the old equipment used by existing manufacturers,

which is only about 40 meters long. It has 4 production lines, 3 factories 25 warehouses nationwide, and 120 cooperative dealers.

This advanced production process not only ensures the high quality and high performance of Lighting Tiles but also makes them unique in the market.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

Details Displaying

|

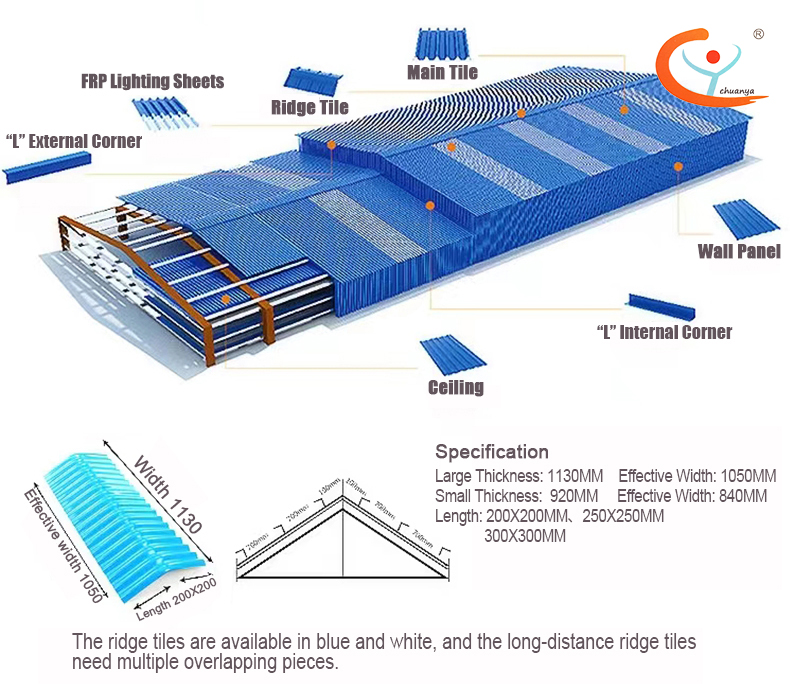

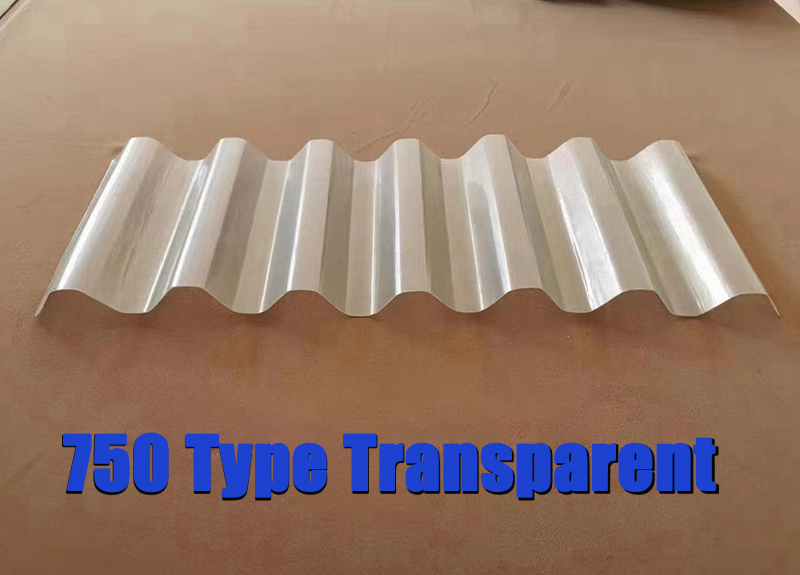

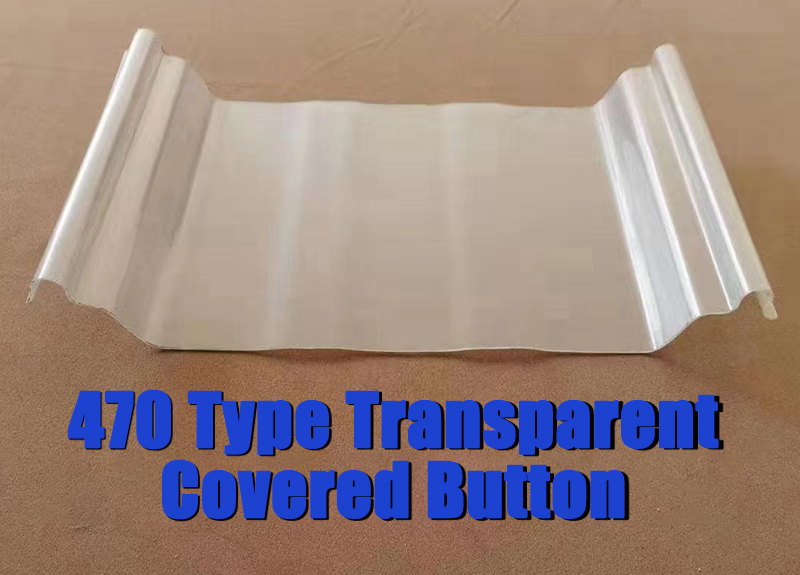

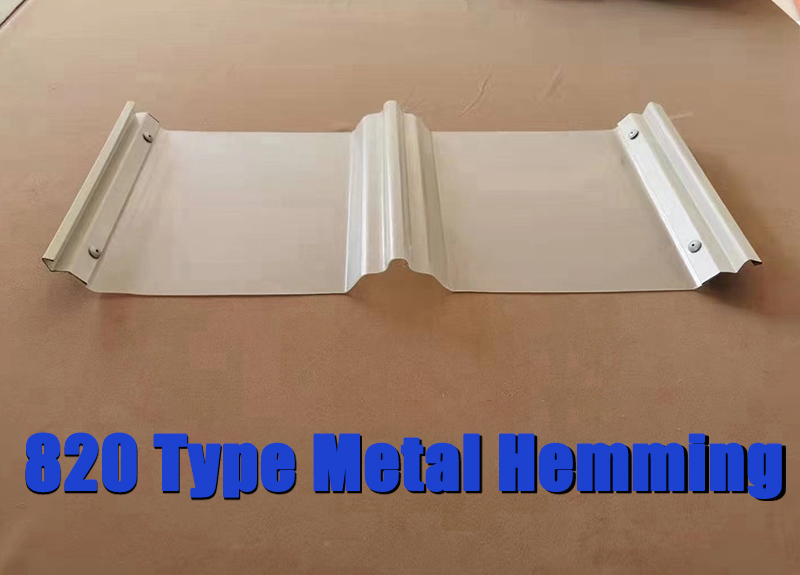

| Panel Classification for FRP Lighting Sheets, Chuanya Roof Tile |

Classification of FRP Lighting Sheets(Chuanya Roof Tiles):

FRP FRP Lighting Sheets should be composed of high-performance upper film, reinforced polyester, and glass fiber.

The upper film should play a good role in anti-ultraviolet and anti-static. Anti-ultraviolet is to protect the polyester of FRP Lighting Panels from yellowing and aging, and premature loss of light transmission properties.

Anti-static ensures that the dust on the surface is easily washed away by rain or wind, maintaining a clean and beautiful surface.

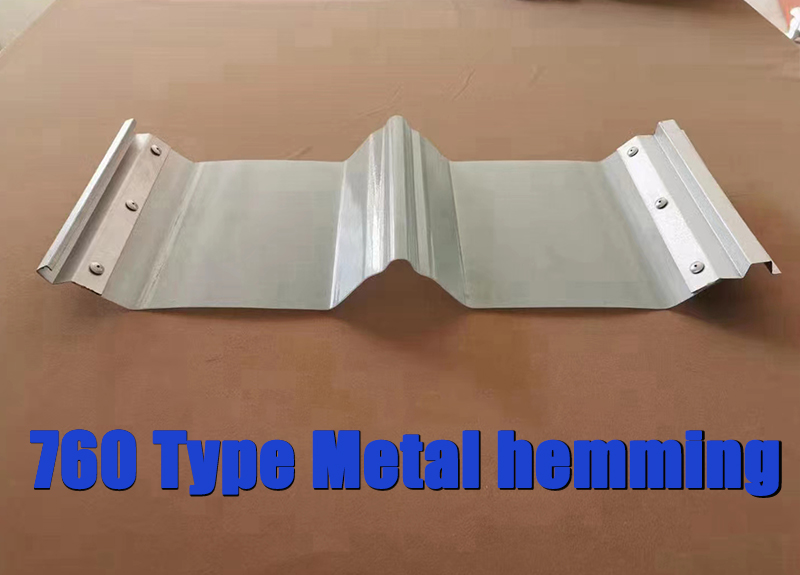

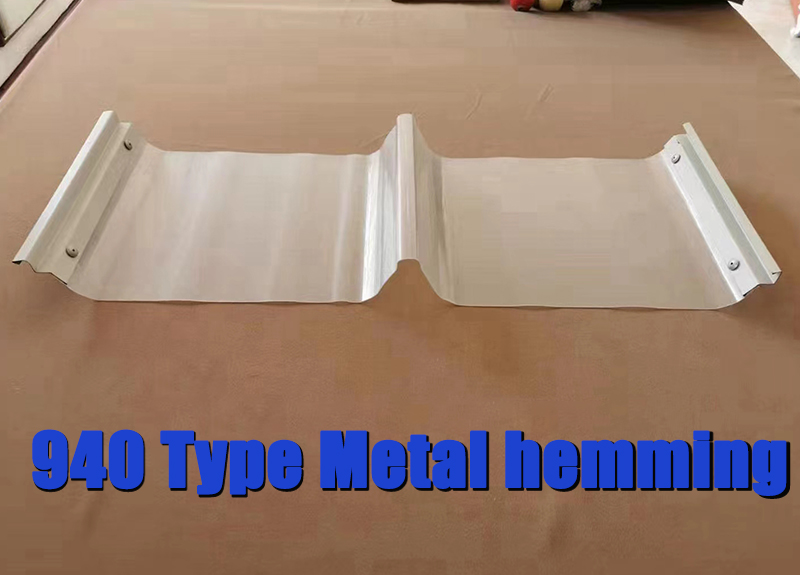

Common models are:

400 Type/ 470 Type/ 666 Type/ 750 Type/ 760 Type/ 475 Type/ 478 Type/ 840 Type/ 820 Type/ 860 Type/ 900 Type/ 950 Type/ 960 Type/ 980 Type/ 1000 Type/ 1050 Type/ 1070 Type/ 1230 Type/ 1260 Type/ 1350 Type/ 1200 Type/ 1500 Type

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

| Light Transmittance of FRP Lighting Sheets, Chuanya Roof Tile |

Features of lighting tiles:

1. Maintain stable performance within the temperature range of -40℃ to 120℃, without high-temperature softening and high cold embrittlement; it can also be designed into a double-layer structure with better thermal insulation effect, especially suitable for winter production in farms in the northern cold regions.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

| FRP Lighting Sheets not easy to corrode or oxidize, Chuanya Roof Tile |

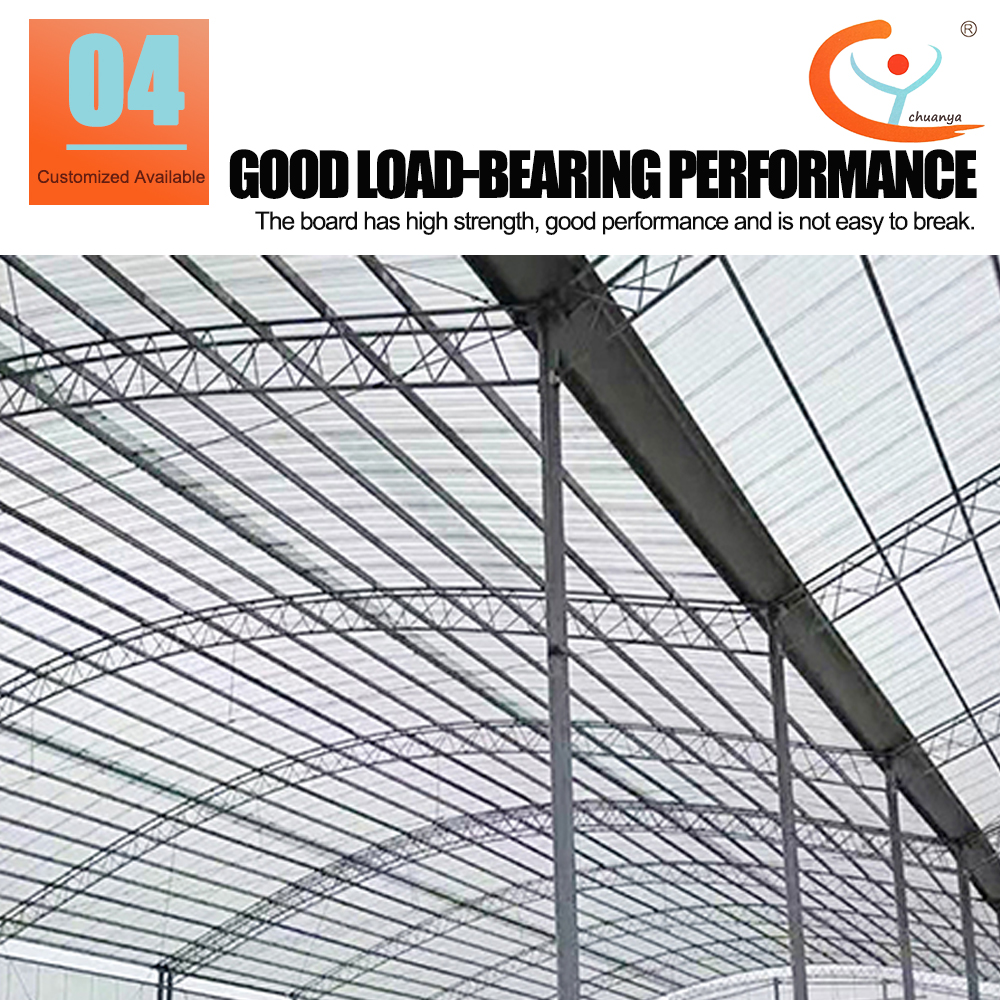

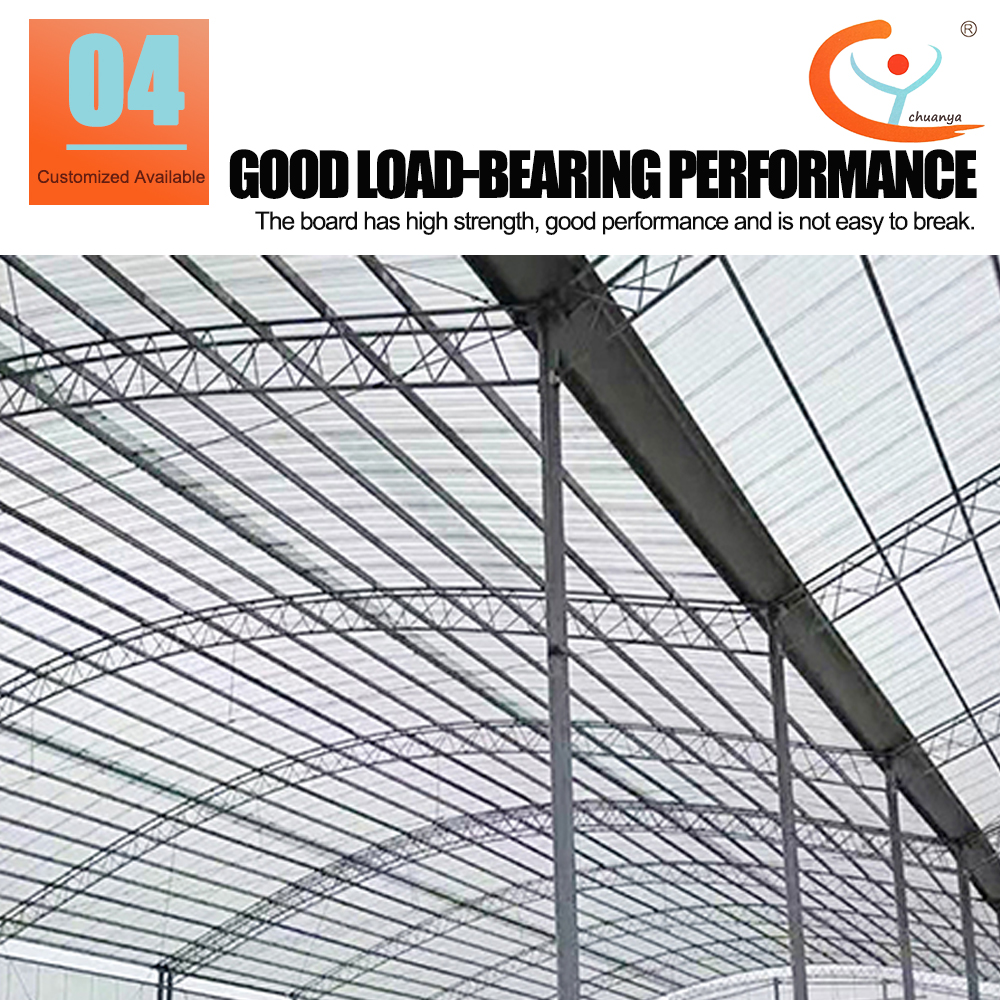

2. Anti-shattering, super impact resistance, can block the impact of wind, snow, and hail, and avoid cracking and leakage of nail holes. 3. Easy to clean, easy to clean, no special care required.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

| High Temperature Resistance for FRP Lighting Sheets, Chuanya Roof Tile |

4. The lighting light is diffuse, the light is soft, the light transmittance is high, and it can effectively block most ultraviolet rays

5. When a fire occurs, the indoor smoke is discharged after rapid combustion, which can reduce casualties in the fire, and no molten droplets are produced during the combustion process, which can effectively protect the safety of on-site personnel

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

| Good loadbearing for FRP Lighting Sheets, Chuanya Roof Tile |

6. It is corrosion-resistant, acid-resistant, and alkali-resistant, suitable for roofs of chemical workshops, such as fertilizer plants and electroplating plants

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

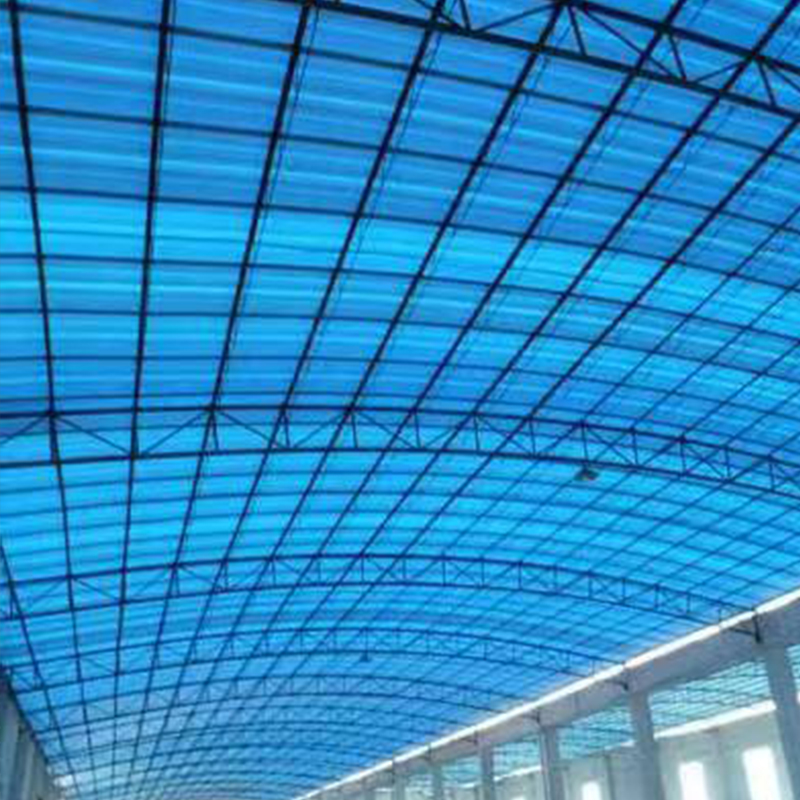

| Case displaying of FRP Lighting Sheets for usage, Chuanya Roof Tile |

Usage of the FRP Lighting Sheets:

Industrial factory roof and wall lighting, agricultural vegetable greenhouse insulation lighting, public sports stadium roof lighting, special requirements of flame retardant, anti-corrosion and heat insulation of buildings, as well as warehouses, greenhouses, stations, docks, airports, commercial buildings, steel structures and many other lighting fields.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

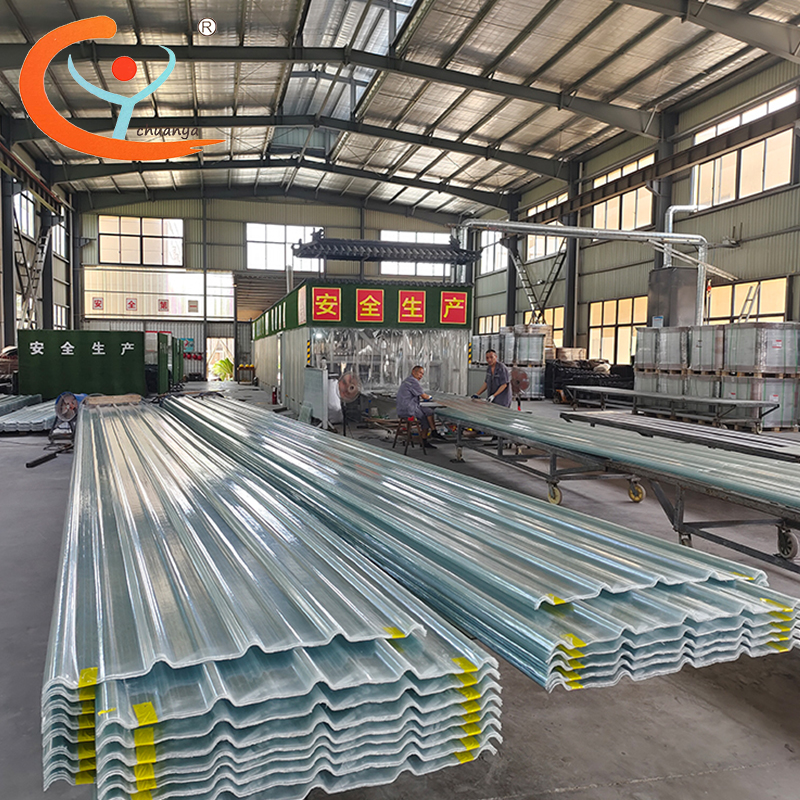

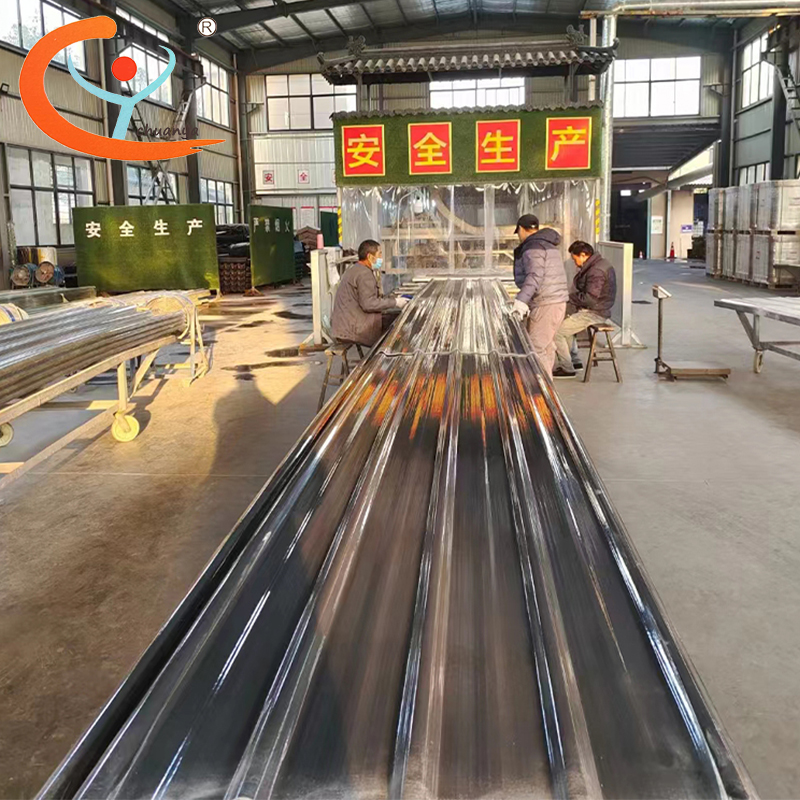

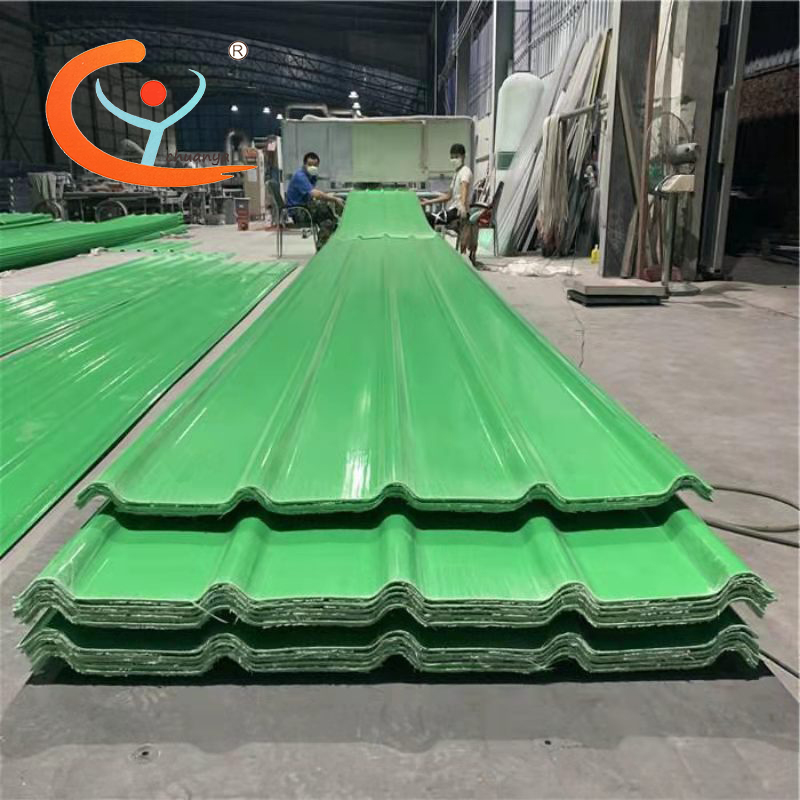

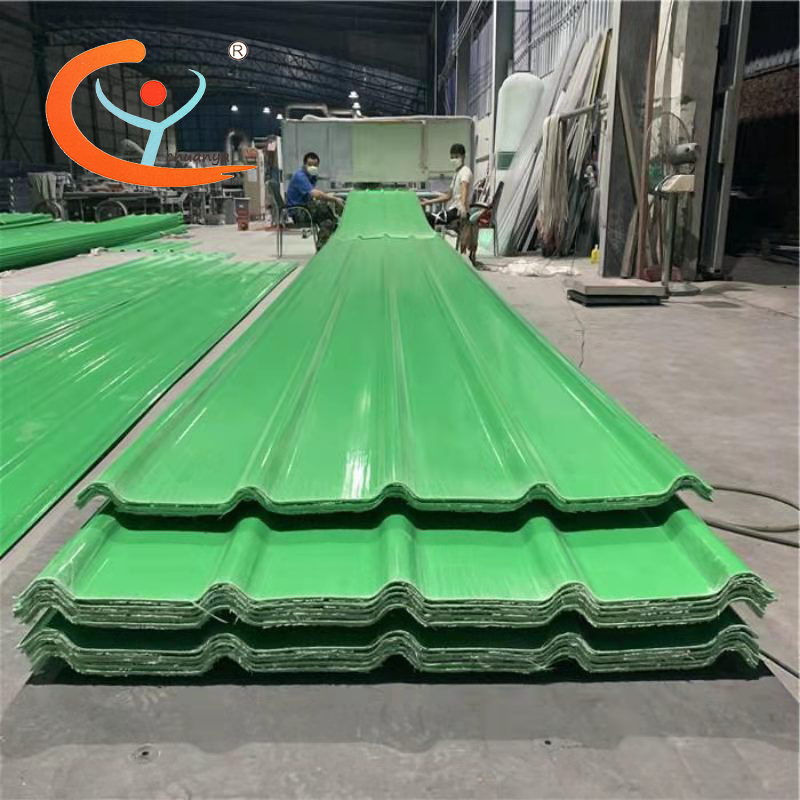

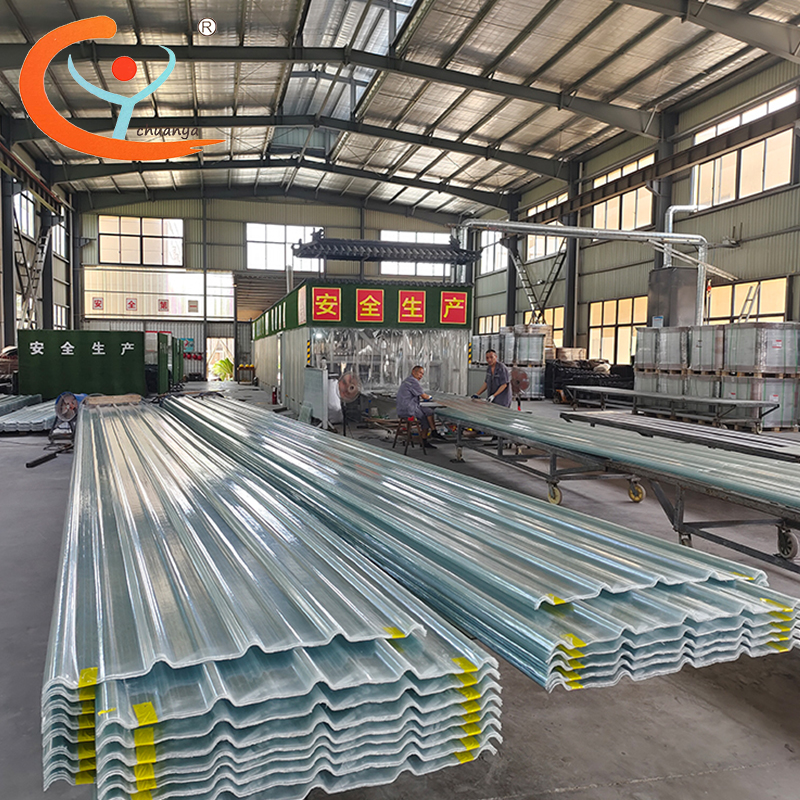

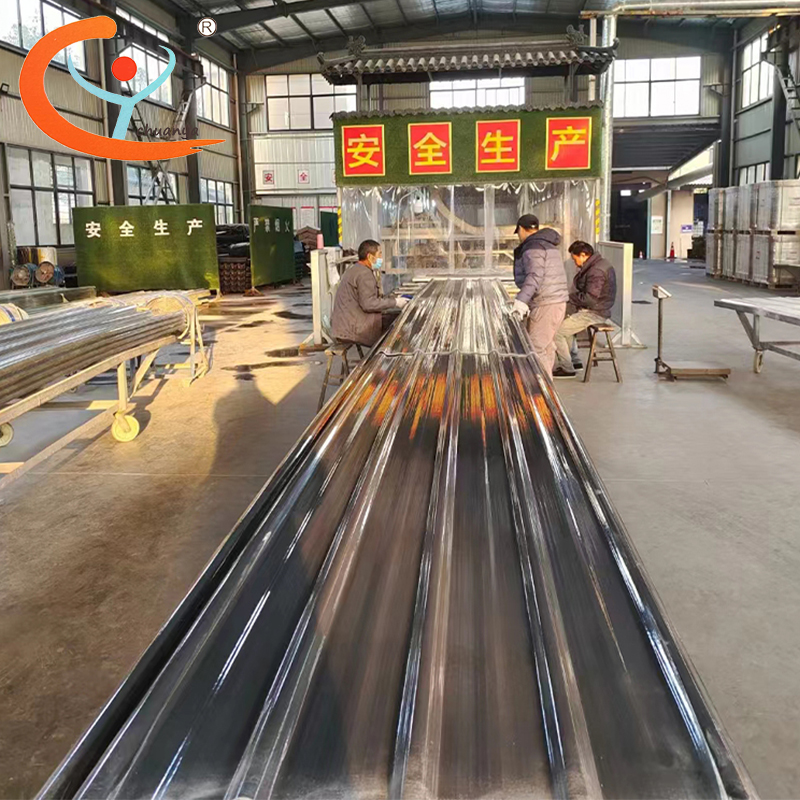

| Production Displaying for FRP Lighting Sheets, Chuanya Roof Tile |

FRP skylight tile is a kind of skylight material made of fiberglass reinforced plastic (FRP for short).

Its main components include unsaturated polyester resin and glass fiber and its products (such as glass cloth, tape, felt, yarn), which are made through a continuous production process.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

Installation

|

|

|

|

| The FRP Lighting Sheets used for Atrium, Chuanya Roof Tiles |

The FRP Lighting Sheets used for rooftop cover, Chuanya Roof Tiles |

The FRP Lighting Sheets used for rooftop cover, Chuanya Roof Tiles |

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

Before fixing the FRP Lighting Sheet, a pilot hole must be made. The hole diameter must be larger than 50% of the diameter of the fixing screw to avoid the internal stress caused by thermal expansion and contraction from cracking the skylight tile.

2. The FRP Lighting Sheet is fixed with aluminum profile fasteners, and the corrugated skylight tile is fixed with a skylight tile bracket and self-tapping screws, and then sealed with glue. The location of the skylight tile is generally set in the middle of the span.

3. When the FRP Lighting Sheet and the steel plate are overlapped longitudinally, there must be a minimum overlap of 200mm, and two water stops must be attached.

4. The FRP Lighting Sheet is connected with the self-tapping screws and must have a cover plate. The sun panel has large deformation due to hot and cold and is easily cut by self-tapping screws. Therefore, a larger hole should be opened at the self-tapping screw point of the sun panel. The elasticity of the FRP Lighting Sheet should be considered when installing the skylight panel.

5. When fixing the FRP Lighting Sheet, a good flashing gasket must be used to place it between the screw and the FRP Lighting Sheet to facilitate waterproofing and dustproofing. After inserting the flashing gasket into the screw, use an electric drill to lock it into the purlin to complete the fixing of the skylight board.

6. The FRP Lighting Sheet do not need to be overlapped within 12m, but overlap is required if it exceeds 12m. The overlap length is 200-400mm. Apply two layers of sealant at the overlap. The horizontal overlap does not need to be trimmed. The overlap of the longitudinal color steel plate depends on the plate type.

Ordinary corrugated steel plates are generally not considered to be trimmed. They are directly fixed to the color plate with self-tapping screws and sealed with sealant. The bite plate needs to be trimmed.

7. When constructing FRP Lighting Sheet, it is strictly forbidden to step directly on the crest to avoid cracking of the FRP Lighting Sheet.

A 1200mmx300mm (length x width) non-slip thick wooden board must be placed in the horizontal position of the FRP Lighting Sheet, and the foot must be stepped on it to make the guide holes and fix the screws of the FRP Lighting Sheet.

Hangzhou Chuanya Building Materials Co., Ltd, produced FRP Lighting Sheet. Mainly is made of fiberglass, UV Film with excellent anti-corrosion performance, and unsaturated Polyester Resin as the adhesive.

After molding, cooling, re-extrusion and other processes, high-quality FRP skylights are produced.

High light transmittance and UV resistance: The light of FRP skylight tiles is presented in the form of diffuse light, which is soft and not dazzling. At the same time, it maintains high light transmittance, which can effectively block most ultraviolet rays and ensure safe use.

|

|

|

|

|

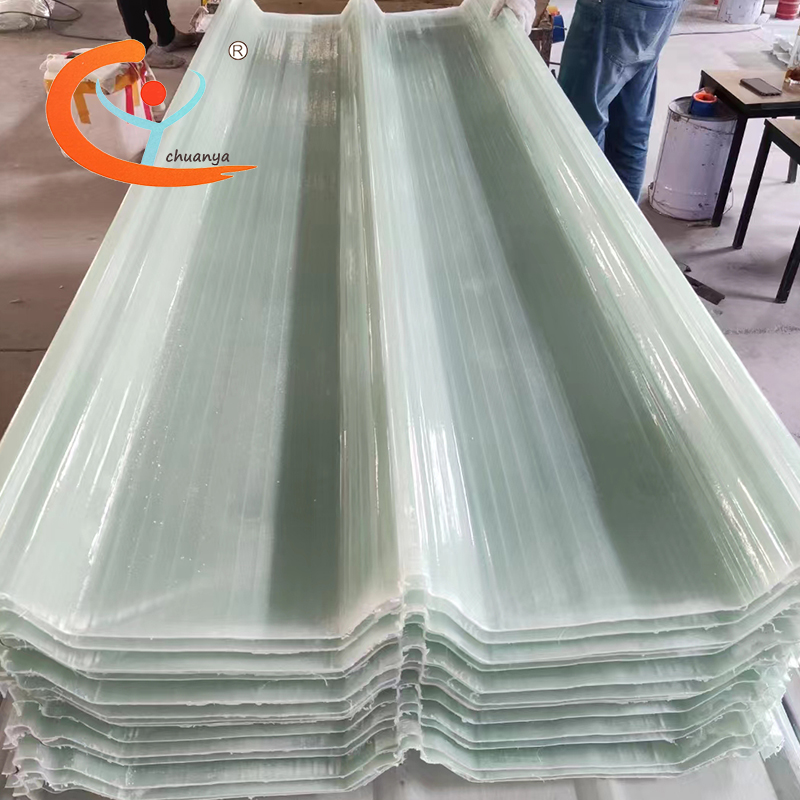

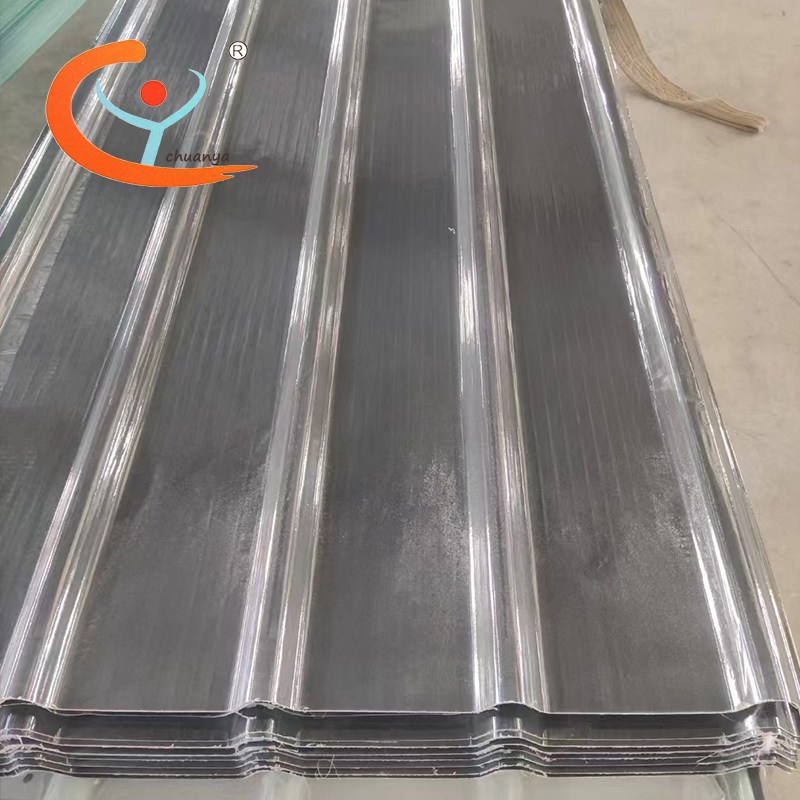

| FRP Lighting Sheets After mold shaping, Chuanya Roof Tiles |

FRP Lighting Sheets through Roller Shaping, Chuanya Roof Tiles |

FRP Lighting Sheets in Cutting Against Customized, Chuanya Roof Tiles |

FRP Lighting Sheets change UV Film Roil, Chuanya Roof Tiles |

|

|

|

|

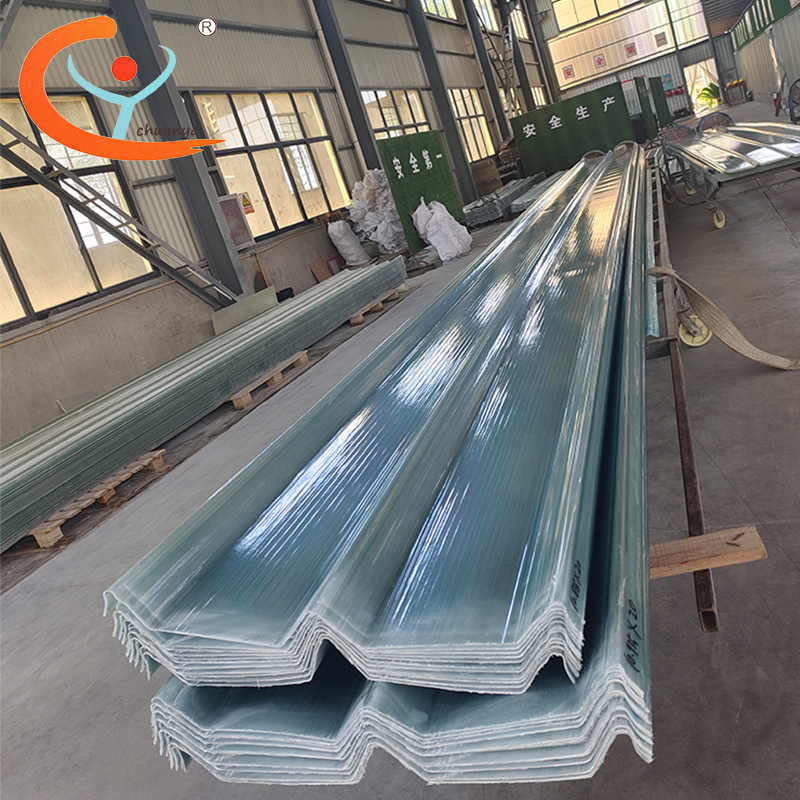

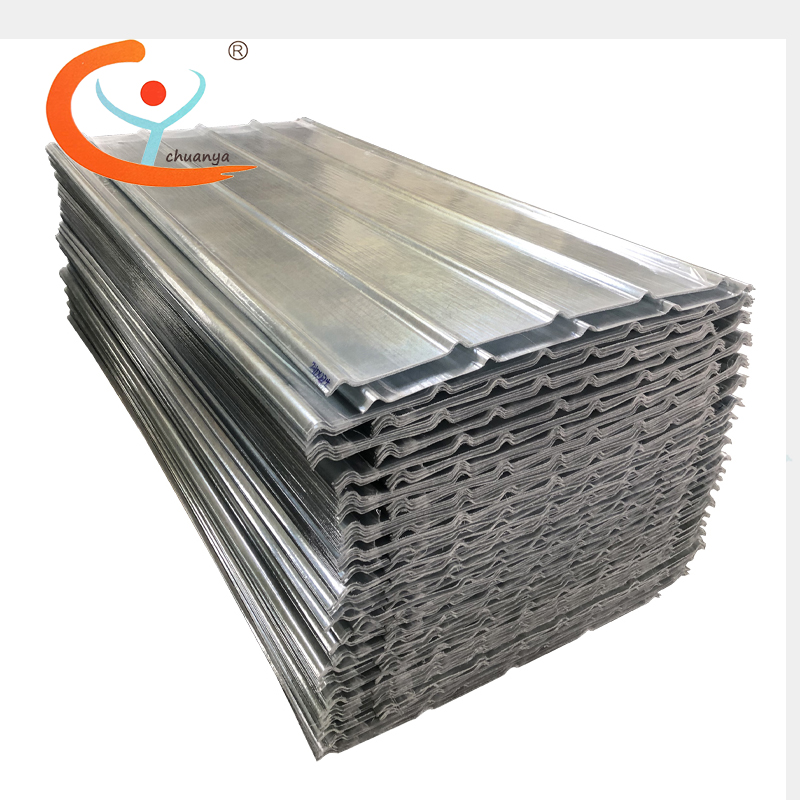

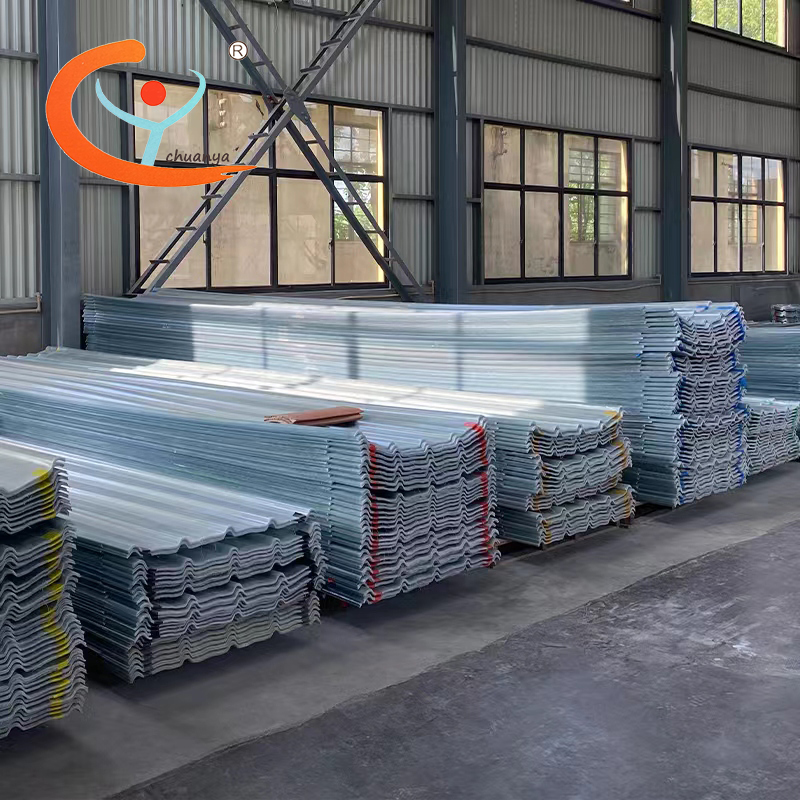

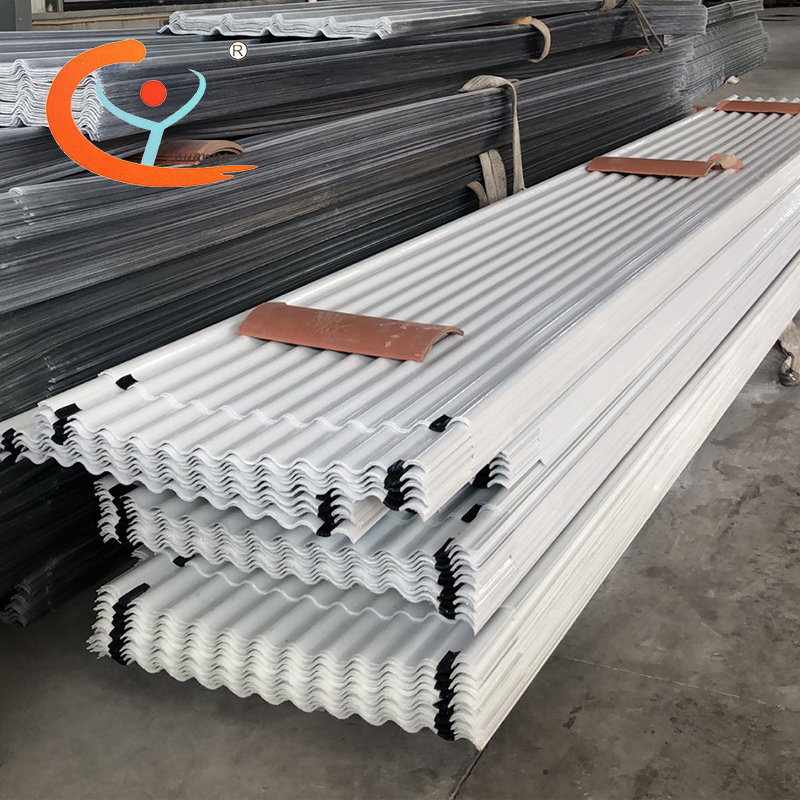

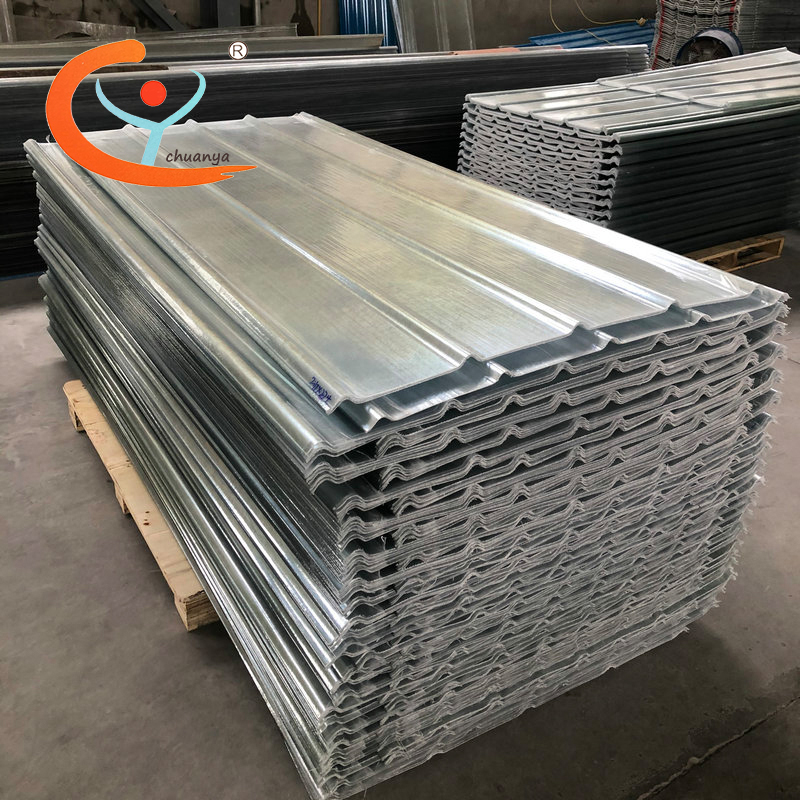

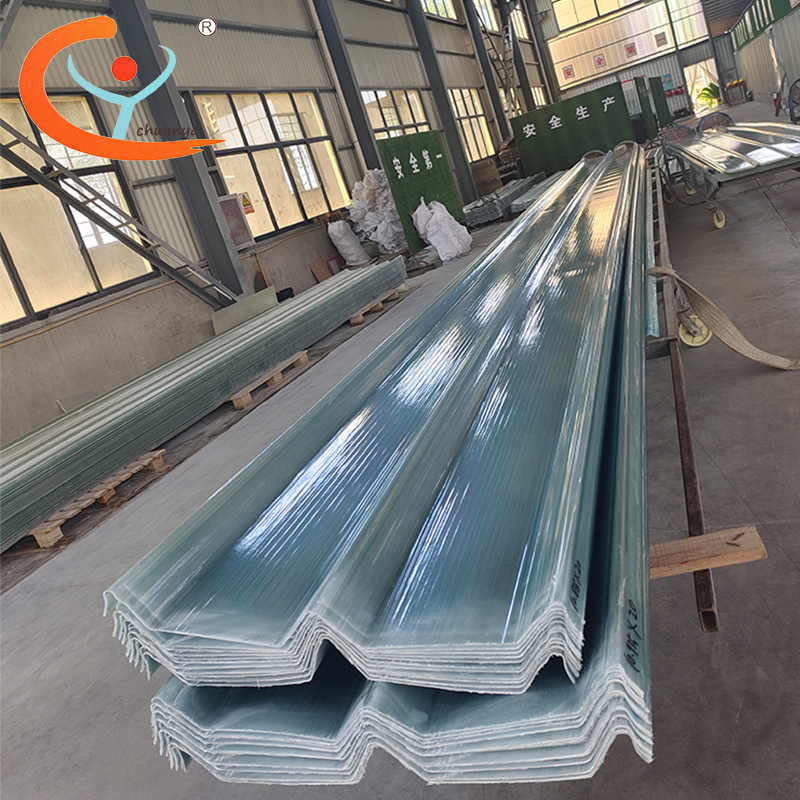

| Shipment for FRP Lighting Sheets, Chuanya Roof Tile |

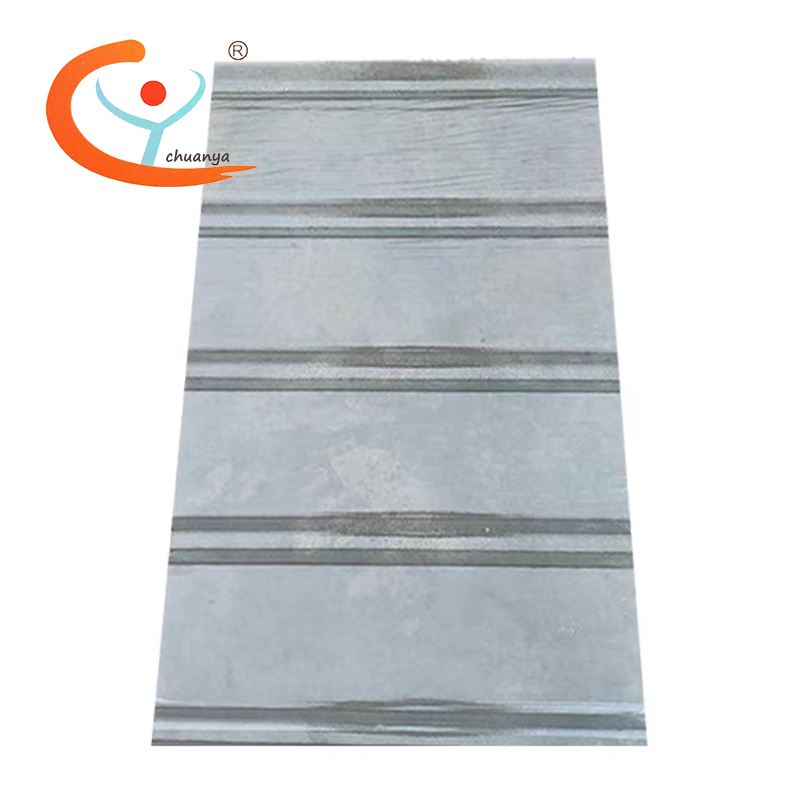

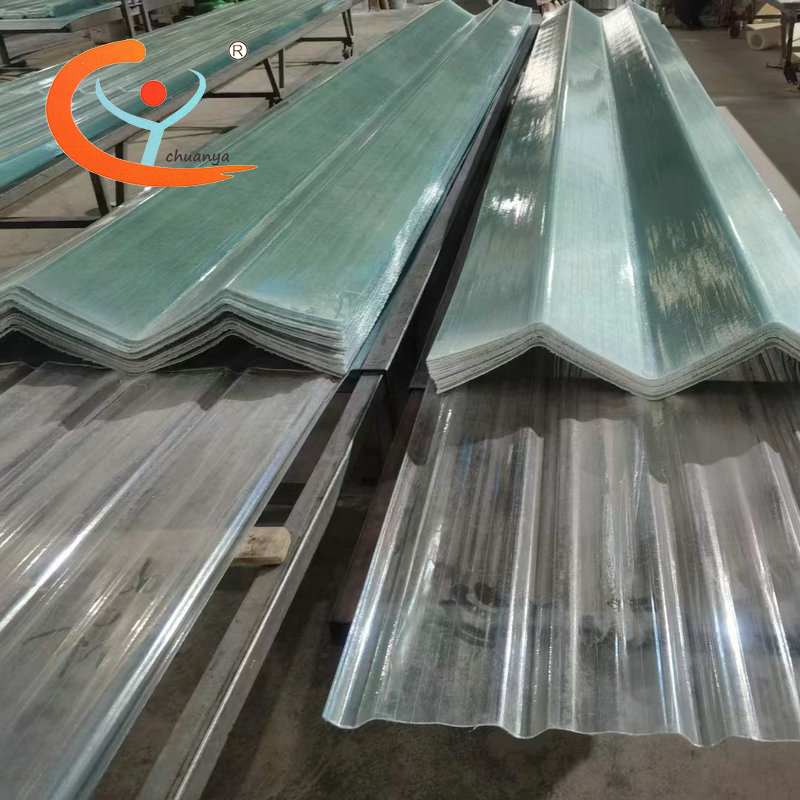

Transparent Type of FRP Lighting Sheets in stock, Chuanya Roof Tile |

FRP Lighting Sheets with black in Production, Chuanya Roof Tile |

Transparent Type of FRP Lighting Sheets in Production, Chuanya Roof Tile |

Product Performance of FRP Lighting Sheet,

FRP skylight tiles are not only of various types, but each type has a unique performance.

For example, transparent FRP skylight tiles have excellent light transmittance and can meet high requirements for light; while UV-resistant ones can effectively resist the erosion of ultraviolet rays and ensure durability for long-term use.

In addition, heat-insulating FRP skylight tiles perform well in heat preservation and provide effective energy-saving solutions for various types of buildings.

At the same time, the emergence of colored FRP skylight tiles provides designers with a rich variety of color options to meet different aesthetic needs.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

Shipment

Hangzhou Chuanya Building Materials Co., Ltd, produced FRP Lighting Sheet.

Mainly is made of fiberglass, UV Film with excellent anti-corrosion performance and unsaturated Polyester Resin as the adhesive.

After molding, cooling, re-extrusion and other processes, high-quality FRP skylights are produced.

High light transmittance and UV resistance: The light of FRP skylight tiles is presented in the form of diffuse light, which is soft and not dazzling. At the same time, it maintains high light transmittance, which can effectively block most ultraviolet rays and ensure safe use.

Daylighting Roof Tile -- > Transparent Roof Tile made by Hangzhou Chuanya Building Material Co., Ltd

|

|

|

|

|

| FRP Lighting Sheets manufacturer wholesale, Chuanya Roof Tiles |

FRP Lighting Sheets through Roller Shaping, Chuanya Roof Tiles |

FRP Lighting Sheets with transparent shipped on a truck, Chuanya Roof Tiles |

FRP Lighting Sheets factory dellivery directly, Chuanya Roof Tiles |

English

English Español

Español عربى

عربى

Email:

Email: Phone:

Phone: Adress:

Adress: