Modern construction increasingly prioritizes energy efficiency and occupant well-being, driving demand for daylighting technologies that balance natural illumination with structural performance. Fiberglass Reinforced Plastic (FRP) daylighting panels represent a significant advancement in this space, offering distinctive properties compared to conventional roofing and wall systems.

Understanding Daylighting Panel Fundamentals Daylighting panels are translucent building components designed to transmit natural light into interior spaces while maintaining weather protection. Unlike fully transparent materials, they diffuse sunlight to reduce glare and heat concentration. Traditional solutions like polycarbonate or acrylic sheets have served this purpose for decades, but FRP composites introduce alternative material science with unique advantages.

Material Composition and Performance Characteristics FRP daylighting panels consist of woven glass fibers embedded in a polymer resin matrix. This hybrid structure creates inherent capabilities:

Light Transmission Properties The resin formulation and fiber orientation can be engineered to achieve specific translucency levels. Some configurations transmit soft, evenly distributed light comparable to north-facing studio windows, reducing the need for artificial lighting during daytime hours.

Structural Resilience The embedded glass fibers provide tensile strength absent in homogeneous plastics. This reinforcement helps panels withstand environmental stresses including wind uplift, thermal expansion/contraction cycles, and incidental impact better than many non-reinforced alternatives.

|

Feature |

FRP Daylighting Panels |

Polycarbonate Panels |

Glass Systems |

|

Light Diffusion |

Even distribution |

Variable clarity options |

Directional transmission |

|

Impact Resistance |

Moderate to high |

High |

Low |

|

Installation Weight |

Lightweight |

Lightweight |

Substantial |

|

Structural Flexibility |

Moderate curvature tolerance |

High curvature tolerance |

Limited flexibility |

|

Maintenance Needs |

Simple cleaning |

Potential scratching concerns |

Breakage risk |

Environmental Resistance Quality formulations demonstrate resistance to UV degradation, moisture absorption, and chemical exposure from industrial or coastal atmospheres. This reduces yellowing and embrittlement over time compared to early-generation plastics.

Practical Considerations for Specifiers When evaluating daylighting systems, several factors influence suitability:

Thermal Performance While transmitting visible light, FRP composites can be formulated to block infrared wavelengths. This selective transmission helps manage solar heat gain – a crucial consideration for energy modeling in different climates.

Acoustic Properties Multilayer FRP constructions can provide sound dampening characteristics, beneficial for facilities where rainfall noise or external acoustics require mitigation.

Installation Requirements Most FRP daylighting panels install using standard roofing techniques. Compatibility with metal framing systems and conventional sealants simplifies integration into new builds or retrofits. Proper detailing around penetrations and edges remains critical for long-term weathertight performance.

Fire Safety Profiles Certain FRP formulations achieve fire-resistance ratings suitable for commercial applications. Specifiers should verify local compliance regarding smoke development and flame spread characteristics.

Comparative Material Perspectives Daylighting solutions exist across multiple material categories:

· Polycarbonate: Noted for impact resistance but prone to scratching

· Acrylic: Offers exceptional clarity but lower thermal tolerance

· Glass Block: Provides security and insulation with limited design flexibility

· Metal Roofing w/Skylights: Creates illumination points rather than continuous zones

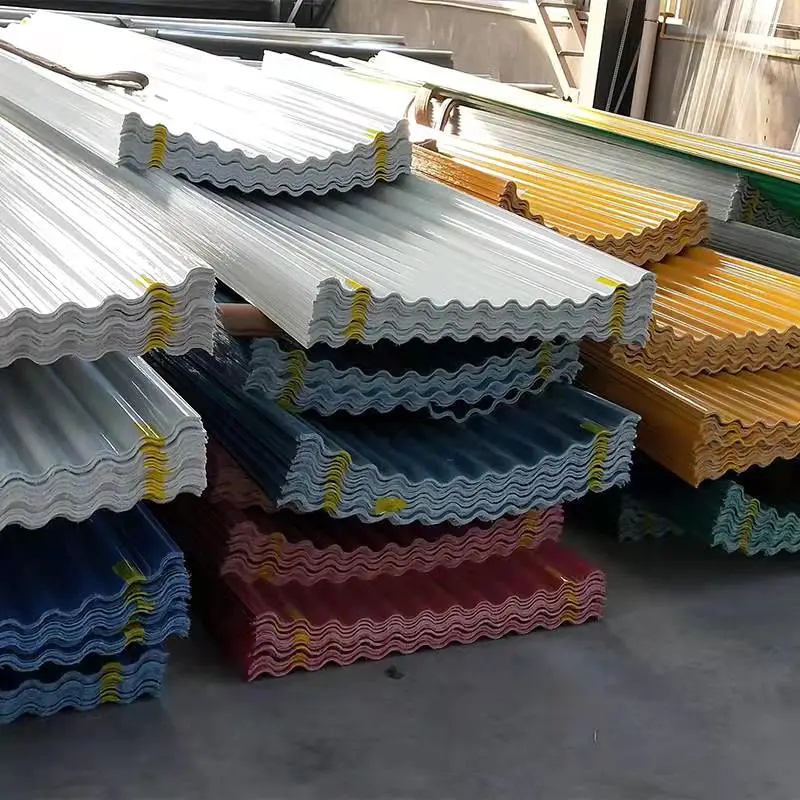

FRP panels occupy a middle ground – offering diffuse light distribution across larger uninterrupted spans while maintaining the weight advantages of composite materials. Their ribbed or corrugated profiles often match adjacent metal roofing for visual continuity.

Innovations in Daylighting Solutions: Exploring FRP Panel Applications

Modern construction increasingly prioritizes natural light integration, driving demand for specialized daylighting systems. Fiberglass Reinforced Plastic (FRP) daylighting panels represent a category of building materials designed to transmit sunlight while offering structural functionality. These translucent panels leverage composite technology to create roofing and wall elements that balance illumination needs with practical performance requirements.

Understanding FRP Daylighting Technology FRP daylighting panels consist of polyester resin reinforced with glass fibers, formulated to allow controlled light transmission. Unlike conventional transparent materials, these panels diffuse sunlight evenly, reducing glare and hot spots while maintaining brightness. The embedded fiberglass grid provides tensile strength, enabling the panels to withstand structural loads comparable to opaque roofing materials. This combination addresses two fundamental needs: bringing natural light into interior spaces and maintaining building envelope integrity.

Functional Characteristics and Performance Light Transmission Properties The light-diffusing quality of these panels creates uniform illumination without directional shadows. This characteristic proves valuable in environments like warehouses, manufacturing facilities, and agricultural buildings where consistent overhead lighting enhances visibility and reduces dependence on artificial lighting during daylight hours. Different formulations offer varying light transmission levels to suit specific application requirements.

Material Resilience Composite construction provides inherent resistance to environmental factors. The panels typically demonstrate tolerance to moisture exposure without corrosion or degradation. UV-resistant formulations help maintain light transmission capabilities and structural integrity when exposed to sunlight. Thermal stability allows the material to withstand temperature variations common in roofing applications.

Structural and Safety Considerations The reinforced nature provides impact resistance appropriate for overhead installation. Fire-retardant formulations are available, contributing to building safety compliance. When properly engineered and installed, the panels can withstand typical snow loads and moderate foot traffic for maintenance access.

Environmental and Operational Aspects The translucency contributes to energy conservation by reducing reliance on artificial lighting. Some formulations incorporate thermal insulation properties, helping moderate interior temperatures. Long-term maintenance generally involves periodic cleaning to maintain light transmission, without specialized treatments or coatings typically required.

Addressing Implementation Challenges Potential concerns include condensation management, addressed through proper ventilation design and vapor barrier integration. Noise transmission during precipitation can be mitigated with acoustic underlayments or structural isolation techniques. Cosmetic preferences vary, though modern manufacturing offers textured finishes and tinted options to complement architectural aesthetics.

Technical Development Focus Chuanyabuilding approaches daylighting solutions with recognition of diverse architectural requirements. Development prioritizes practical performance aspects: consistent light diffusion properties across production batches, compatibility with standard construction methods, and formulation stability under prolonged environmental exposure. Material selection emphasizes functional longevity and compatibility with conventional maintenance practices.

Application Diversity These panels serve multiple sectors:

· Industrial Facilities: Illuminating production floors while providing weather protection

· Agricultural Buildings: Supporting plant growth through diffused natural light

· Commercial Spaces: Enhancing atriums, covered walkways, and retail environments

· Recreational Facilities: Providing weather-protected daylight in pools and sports complexes

Maintenance Protocols and Longevity Routine cleaning with mild detergents maintains light transmission efficiency. Periodic inspections ensure sealant integrity at joints and penetrations. Unlike materials requiring protective coatings, these panels maintain performance through inherent material properties. Proper installation remains crucial for achieving expected service duration.

Future Development Trajectories Material science advancements continue to enhance functional characteristics. Current research explores improved thermal performance integration, expanded color consistency options, and specialized formulations for unique environmental conditions. Manufacturing refinements aim to increase production efficiency while maintaining quality standards.

Practical Selection Guidance Project teams might consider these factors:

· Required light transmission levels for intended activities

· Climate-specific performance needs (snow loads, wind uplift, UV exposure)

· Compatibility with existing structural systems

· Maintenance accessibility expectations

· Architectural integration requirements

Chuanyabuilding supports these considerations through technical documentation addressing application-specific implementation details. The company's development philosophy centers on creating reliable daylighting solutions that perform consistently within broader building systems, acknowledging that successful integration requires attention to both product capabilities and installation practices.

English

English Español

Español عربى

عربى

Email:

Email: Phone:

Phone: Adress:

Adress: